1. I-brazing material

(1) I-Titanium nama-alloys ayo ayisisekelo akuvamile ukuba ifakwe i-solder ethambile.Izinsimbi zokugcwalisa ezisetshenziselwa ukubhula ikakhulukazi zifaka isisekelo sesiliva, isisekelo se-aluminium, isisekelo se-titanium noma isisekelo se-titanium zirconium.

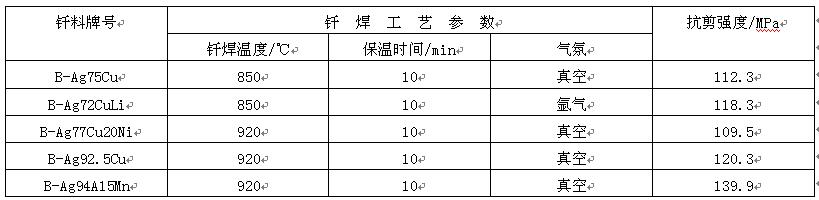

I-solder esekelwe esiliva isetshenziselwa ikakhulukazi izingxenye ezinezinga lokushisa elingaphansi kuka-540 ℃.Amalunga asebenzisa i-solder yesiliva ehlanzekile anamandla aphansi, kulula ukuqhekeka, futhi amelana kabi nokugqwala kanye nokumelana ne-oxidation.Izinga lokushisa elishisayo le-Ag Cu solder liphansi kunelesiliva, kodwa ukumanzisa kuyehla ngokunyuka kokuqukethwe kwe-Cu.Isoda ye-Ag Cu equkethe inani elincane lika-Li ingathuthukisa ukumanzisa kanye nezinga le-alloying phakathi kwe-solder nesisekelo sensimbi.I-AG Li solder inezici zendawo encibilikayo ephansi kanye nokunciphisa okunamandla.Ilungele i-brazing titanium kanye ne-titanium alloys endaweni evikelayo.Nokho, i-vacuum brazing izongcolisa isithando somlilo ngenxa yokuhwamuka kwe-Li.I-Ag-5al- (0.5 ~ 1.0) I-Mn filler metal iyinsimbi ekhethwayo yokugcwalisa izingxenye zengxube ye-titanium enezindonga ezincane.I-brazed joint ine-oxidation enhle kanye nokumelana nokugqwala.Amandla e-shear we-titanium ne-titanium alloy joints aboshwe ngensimbi yokugcwalisa isisekelo sesiliva akhonjiswe kuThebula 12.

Ithebula 12 lamapharamitha enqubo yokubraziza namandla ahlangene we-titanium ne-titanium alloys

Ukushisa kwe-brazing ye-aluminium esekelwe ku-solder kuphansi, okungeke kubangele ukuvela kwe-titanium alloy β ukuguqulwa kweSigaba kunciphisa izidingo zokukhethwa kwezinto zokulungisa i-brazing kanye nezakhiwo.Ukusebenzisana phakathi kwensimbi yokugcwalisa kanye nesisekelo sensimbi kuphansi, futhi ukuhlakazeka nokusabalalisa akubonakali, kodwa ipulasitiki yensimbi yokugcwalisa ilungile, futhi kulula ukugoqa insimbi yokugcwalisa kanye nesisekelo sensimbi ndawonye, ngakho kunjalo. ifaneleka kakhulu i-brazing titanium alloy radiator, isakhiwo sezinyosi kanye nesakhiwo se-laminate.

Ama-fluxes asekelwe ku-titanium noma i-titanium zirconium ngokuvamile aqukethe i-Cu, i-Ni nezinye izakhi, ezingasakazeka ngokushesha ku-matrix futhi zisabele nge-titanium phakathi nokugqama, okuholela ekugqwaleni kwe-matrix nasekwakhekeni kongqimba oluphukayo.Ngakho-ke, izinga lokushisa lokubamba kanye nesikhathi sokubamba kufanele kulawulwe ngokuqinile ngesikhathi sokubhula, futhi akufanele kusetshenziselwe ukubrasa izakhiwo ezinezindonga ezincane kakhulu ngangokunokwenzeka.I-B-ti48zr48be iyi-solder ye-Ti Zr evamile.Inokumanzisa okuhle ku-titanium, futhi isisekelo sensimbi asinakho ukuthambekela kokukhula okusanhlamvu ngesikhathi sokubhula.

(2) Izinsimbi zokugcwalisa i-brazing ze-zirconium nama-base alloys brazing ye-zirconium nama-base alloys ikakhulukazi afaka i-b-zr50ag50, b-zr76sn24, b-zr95be5, njll., esetshenziswa kabanzi ekubhubhiseni amapayipi e-zirconium alloy we-reactors yamandla enyukliya.

(3) I-brazing flux kanye nomoya ovikelayo we-titanium, i-zirconium kanye nama-alloys ayisisekelo angathola imiphumela egculisayo ku-vacuum ne-inert atmosphere (i-helium ne-argon).I-argon yokuhlanzeka okuphezulu izosetshenziselwa ukubhula okuvikelwe kwe-argon, futhi indawo yamazolo kufanele ibe -54 ℃ noma ngaphansi.I-fluoride ekhethekile equkethe i-fluoride ne-chloride yensimbi engu-Na, K kanye ne-Li kufanele isetshenziselwe ukubhula amalangabi.

2. Ubuchwepheshe be-Brazing

Ngaphambi kokubopha, ingaphezulu kufanele lihlanzwe kahle, likhishwe amafutha kanye nefilimu ye-oxide.Ifilimu ye-oxide ewugqinsi kufanele isuswe ngendlela yomshini, indlela yokuqhuma kwesihlabathi noma indlela yokugeza usawoti oncibilikisiwe.Ifilimu encane ye-oxide ingaqedwa kusixazululo esiqukethe 20% ~ 40% nitric acid kanye 2% hydrofluoric acid.

I-Ti, i-Zr kanye nama-alloys awo awavunyelwe ukuthintana nendawo ehlangene ngomoya ngesikhathi sokushisisa ngokushisa.I-Brazing ingenziwa ngaphansi kokuvikelwa kwe-vacuum noma igesi ye-inert.Ukushisa kokungenisa imvamisa ephezulu noma ukufudumeza ekuvikeleni kungasetshenziswa.Ukushisa kwe-induction kuyindlela engcono kakhulu yezingxenye ezincane ezilinganayo, kuyilapho ukugqama esithandweni kunenzuzo kakhulu ezingxenyeni ezinkulu neziyinkimbinkimbi.

I-Ni Cr, i-W, i-Mo, i-Ta nezinye izinto zizokhethwa njengezinto zokushisisa ze-brazing Ti, Zr kanye nama-alloys azo.Izisetshenziswa ezine-graphite eveziwe njengezici zokushisisa akufanele zisetshenziselwe ukugwema ukungcoliswa kwekhabhoni.I-Brazing fixation izokwenziwa ngezinto eziqinile ezinamandla ezinga lokushisa eliphezulu, i-coefficient yokunweba okushisayo efanayo ku-Ti noma i-Zr, kanye nokuphinda kusebenze okuphansi ngensimbi eyisisekelo.

Isikhathi sokuthumela: Jun-13-2022