1. Ukuba nesibindi

Impahla ye-brazing ye-aluminium ne-aluminium alloys impofu, ikakhulukazi ngenxa yokuthi ifilimu ye-oxide engaphezulu kunzima ukuyisusa.I-Aluminium ihlobene kakhulu nomoya-mpilo.Kulula ukwenza ifilimu le-oxide elicinene, elizinzile futhi eliphakeme i-Al2O3 ngaphezulu.Ngesikhathi esifanayo, ama-alloys e-aluminium aqukethe i-magnesium nawo azokwakha ifilimu ye-oxide ezinzile kakhulu i-MgO.Bazovimbela kakhulu ukumanzisa nokusabalalisa kwe-solder.Futhi kunzima ukususa.Ngesikhathi sokuqhakaza, inqubo yokubopha ingenziwa kuphela nge-flux efanele.

Okwesibili, ukusebenza kwe-aluminium ne-aluminium alloy brazing kunzima.Iphoyinti lokuncibilika le-aluminium ne-aluminium alloy alihlukile kakhulu kulelo lensimbi yokugcwalisa esetshenzisiwe.Ibanga lokushisa ozikhethela lona lokubhula lincane kakhulu.Ukulawulwa okuncane kokushisa okungalungile kulula ukubangela ukushisa ngokweqile noma ngisho nokuncibilika kwensimbi eyisisekelo, okwenza inqubo yokubhula ibe nzima.Amanye ama-alloys e-aluminium aqiniswe ukwelashwa kokushisa azophinda abangele izenzakalo zokuthambisa ezifana nokuguga ngokweqile noma ukucwiliswa kwamanzi ngenxa yokushisisa kwe-brazing, okuzonciphisa izakhiwo zamajoyinti e-brazed.Ngesikhathi sokushisa ilangabi, kunzima ukwahlulela izinga lokushisa ngoba umbala we-aluminium alloy awushintshi ngesikhathi sokushisa, okwandisa nezidingo zezinga lokusebenza komqhubi.

Ngaphezu kwalokho, ukumelana nokugqwala kwe-aluminium ne-aluminium alloy brazed joints kuthinteka kalula yizinsimbi zokugcwalisa kanye nama-fluxes.Amandla e-electrode e-aluminium ne-aluminium alloy ahluke kakhulu ku-solder, okunciphisa ukumelana nokugqwala kwelunga, ikakhulukazi i-solder soldering joint.Ngaphezu kwalokho, ama-fluxes amaningi asetshenziswa ekubhuqeni i-aluminiyamu nama-alloys e-aluminium anokonakala okuqinile.Ngisho noma zihlanzwa ngemva kokubhoboza, ithonya le-fluxes ekuphikiseni ukugqwala kwamalunga ngeke liqedwe ngokuphelele.

2. I-brazing material

(1) Ukubhula kwe-aluminium ne-aluminium alloys kuyindlela engavamile ukusetshenziswa, ngoba ukwakheka namandla e-electrode ensimbi yokugcwalisa i-brazing kanye nesisekelo sensimbi kuhluke kakhulu, okulula ukubangela ukugqwala kwe-electrochemical kokuhlangene.I-solder ethambile ithatha ngokuyinhloko i-zinc based solder kanye ne-tin lead solder, engahlukaniswa ibe yi-solder yokushisa ephansi (150 ~ 260 ℃), i-solder yokushisa ephakathi (260 ~ 370 ℃) kanye ne-solder yokushisa ephezulu (370 ~ 430 ℃) ngokusho izinga lokushisa.Uma kusetshenziswa i-tin lead solder futhi ithusi noma i-nickel ifakwa ngaphambili endaweni ye-aluminium ukuze ibrase, ukugqwala endaweni ehlangene kungavinjelwa, ukuze kuthuthukiswe ukumelana nokubola kwelunga.

I-Brazing ye-aluminium ne-aluminium alloys isetshenziswa kabanzi, njengesiqondiso sokuhlunga, i-evaporator, irediyetha nezinye izinto.Izinsimbi zokugcwalisa ezisekelwe ku-aluminium kuphela ezingasetshenziselwa ukubhula kwe-aluminium nama-alloys e-aluminium, phakathi kwazo izinsimbi ze-aluminium silicon filler zisetshenziswa kakhulu.Ububanzi obuthile bokusebenza namandla okugunda amajoyinti abrazid kukhonjisiwe kuThebula 8 kanye nethebula lesi-9 ngokulandelana.Kodwa-ke, indawo yokuncibilika yalesi solder iseduze nesisekelo sensimbi, ngakho-ke izinga lokushisa lokushisa kufanele lilawulwe ngokuqinile futhi linembile ngesikhathi sokubhula ukuze kugwenywe ukushisa noma ukuncibilika kwensimbi eyisisekelo.

Ithebula lesi-8 lobubanzi bohlelo lwezinsimbi zokugcwalisa i-aluminum ne-aluminium alloys

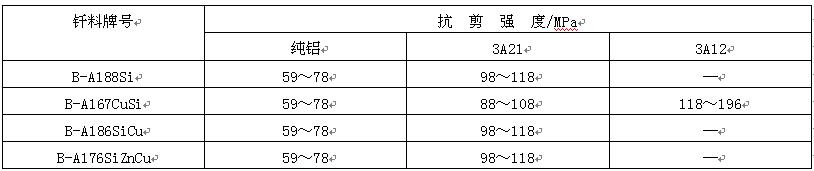

Ithebula 9 lamandla okugunda e-aluminium kanye namajoyinti e-aluminium alloy aboshwe ngezinsimbi ze-aluminium silicon filler

I-aluminium solder ye-silicon ivame ukunikezwa ngendlela yempushana, unamathisele, ucingo noma ishidi.Kwezinye izimo, amapuleti ayinhlanganisela ye-solder ane-aluminium njenge-core kanye ne-aluminium silicon solder njengoba kusetshenziswa i-cladding.Lolu hlobo lwepuleti eliyinhlanganisela ye-solder lwenziwa ngendlela ye-hydraulic futhi luvame ukusetshenziswa njengengxenye yezingxenye zokubopha.Ngesikhathi sokubhula, insimbi yokugcwalisa i-brazing kupuleti eliyinhlanganisela iyancibilika futhi igeleze ngaphansi kwesenzo se-capillary namandla adonsela phansi ukuze kugcwaliswe igebe elihlangene.

(2) I-Flux negesi evikelayo ye-aluminium ne-aluminium alloy brazing, i-flux ekhethekile ivame ukusetshenziswa ukususa ifilimu.I-organic flux esekelwe ku-triethanolamine, njenge-fs204, isetshenziswa ne-solder ethambile enezinga lokushisa eliphansi.Inzuzo yalokhu kugeleza yukuthi inomphumela omncane wokugqwala ensimbi eyisisekelo, kodwa izokhiqiza inani elikhulu legesi, elizothinta ukumanzisa kanye ne-caulking ye-solder.I-flux esebenzayo esekelwe ku-zinc chloride, efana ne-fs203 ne-fs220a, isetshenziswa ngezinga lokushisa eliphakathi nendawo nezinga eliphezulu lokushisa elithambile.I-flux esebenzayo igqwala kakhulu, futhi izinsalela zayo kufanele zisuswe ngemva kokubhula.

Njengamanje, ukugqama kwe-aluminium ne-aluminium alloys kusabuswa ukususwa kwefilimu ye-flux.I-brazing flux esetshenzisiwe ihlanganisa i-chloride based flux kanye ne-fluoride based flux.I-flux esekelwe ku-chloride inamandla aqinile okususa ifilimu ye-oxide kanye noketshezi oluhle, kodwa inomthelela omkhulu olimazayo kusisekelo sensimbi.Izinsalela zayo kufanele zisuswe ngokuphelele ngemuva kokubhula.I-fluoride based flux iwuhlobo olusha lokuguquguquka, olunomphumela omuhle wokususwa kwefilimu futhi akukho ukugqwala kwesisekelo sensimbi.Kodwa-ke, inephuzu eliphezulu lokuncibilika kanye nokuzinza okushisayo kokushisa, futhi ingasetshenziswa kuphela nge-aluminium solder ye-silicon.

Lapho i-brazing aluminium ne-aluminium alloys, i-vacuum, i-neutral noma i-inert atmosphere ivame ukusetshenziswa.Lapho kusetshenziswa i-vacuum brazing, idigri yevacuum ngokuvamile izofinyelela ku-oda lika-10-3pa.Lapho i-nitrogen noma i-argon gas isetshenziselwa ukuvikela, ubumsulwa bayo kufanele bube phezulu kakhulu, futhi indawo yamazolo kufanele ibe ngaphansi kuka -40 ℃

3. Ubuchwepheshe be-Brazing

I-Brazing ye-aluminium ne-aluminium alloys inezidingo eziphezulu zokuhlanza indawo yokusebenza.Ukuze kutholwe ikhwalithi enhle, ibala likawoyela nefilimu ye-oxide ebusweni kufanele kususwe ngaphambi kokubhuqa.Susa ibala lamafutha ebusweni ngesisombululo samanzi se-Na2CO3 ekushiseni kuka-60 ~ 70 ℃ ku-5 ~ 10min, bese ugeza ngamanzi ahlanzekile;Ifilimu ye-oxide engaphezulu ingasuswa ngokufaka i-NaOH isisombululo samanzi ekushiseni kwama-20 ~ 40 ℃ ku-2 ~ 4min, bese igezwa ngamanzi ashisayo;Ngemuva kokukhipha i-oil stain nefilimu ye-oxide ebusweni, i-workpiece izophathwa nge-HNO3 isixazululo samanzi se-gloss ye-2 ~ 5min, bese ihlanzwa emanzini agelezayo futhi ekugcineni yomiswe.I-workpiece ephathwa ngalezi zindlela akufanele ithintwe noma ingcoliswe ngokunye ukungcola, futhi kufanele ifakwe insimbi phakathi kuka-6 ~ 8h.Kungcono ukugcoba ngokushesha uma kungenzeka.

Izindlela zokubhsa ze-aluminium kanye ne-aluminium alloys ikakhulukazi zihlanganisa ukugqama komlilo, i-soldering iron brazing kanye nokushisa kwesithando somlilo.Lezi zindlela ngokuvamile zisebenzisa i-flux in brazing, futhi zinezidingo eziqinile ekushiseni lokushisa kanye nesikhathi sokubamba.Ngesikhathi sokubhula kwe-flame nokugxilisa insimbi, gwema ukushisisa ukugeleza ngokuqondile ngomthombo wokushisa ukuze uvimbele ukugeleza ekushiseni ngokweqile nasekuhlulekeni.Njengoba i-aluminium ingancibilika ku-solder ethambile enokuqukethwe okuphezulu kwe-zinc, ukushisisa kufanele kumiswe uma isihlanganisi senziwe ukugwema ukugqwala kwesisekelo sensimbi.Kwezinye izimo, i-brazing ye-aluminium ne-aluminium alloys ngezinye izikhathi ayisebenzisi i-flux, kodwa isebenzisa izindlela ze-ultrasonic noma ze-scraping ukususa ifilimu.Uma usebenzisa i-scraping ukuze ususe ifilimu ukuze ubhuqe, qala ngokushisisa i-workpiece ekushiseni okushisayo, bese uklebhula ingxenye yokubrawuza ye-workpiece ekugcineni kwentonga ye-solder (noma ithuluzi lokukhuhla).Ngenkathi uphula ifilimu ye-oxide engaphezulu, ukuphela kwe-solder kuzoncibilika futhi kumanzise isisekelo sensimbi.

Izindlela zokubraza ze-aluminium ne-aluminium alloys ikakhulukazi zifaka ukugqama komlilo, ukubhsa kwesithando somlilo, i-dip brazing, i-vacuum brazing kanye ne-gas shielded brazing.I-flame brazing isetshenziselwa kakhulu izingcezu zokusebenza ezincane kanye nokukhiqizwa kwesiqephu esisodwa.Ukuze ugweme ukwehluleka kwe-flux ngenxa yokuxhumana phakathi kokungcola kwe-acetylene kanye ne-flux lapho usebenzisa ilangabi le-oxyacetylene, kufanelekile ukusebenzisa ilangabi lomoya elicindezelwe ngophethiloli ngokunciphisa kancane ukuvimbela i-oxidation yensimbi eyisisekelo.Phakathi ne-brazing ethize, i-brazing flux kanye ne-filler metal ingafakwa endaweni eboshwe kusengaphambili futhi ishiswe ngesikhathi esifanayo ne-workpiece;I-workpiece ingashiswa futhi ekushiseni kwe-brazing kuqala, bese i-solder ecwiliswe nge-flux ingathunyelwa endaweni yokubhoboza;Ngemuva kokuthi i-flux ne-filler metal incibilikile, ilangabi lokushisa lizosuswa kancane ngemva kokuba insimbi yokugcwalisa igcwaliswe ngokulinganayo.

Lapho i-brazing aluminium ne-aluminium alloy esithandweni somoya, insimbi yokugcwalisa i-brazing izosethwa kuqala, futhi i-brazing flux izoncibilika emanzini acwecwe ukuze kulungiswe isisombululo esiwugqinsi esine-concentration engu-50% ~ 75%, bese simbozwa noma sifuthwe phezu. indawo yokubhoda.Inani elifanele le-powder brazing flux lingaphinde limbozwe phezu kwensimbi yokugcwalisa okukhasa kanye nendawo yokubeka, bese i-weldment ehlanganisiwe izofakwa esithandweni sokushisa ukushisa.Ukuze uvimbele isisekelo sensimbi ekushiseni noma ngisho nokuncibilika, izinga lokushisa lokushisa kufanele lilawulwe ngokuqinile.

I-paste noma i-foil solder ngokuvamile isetshenziselwa ukucwiliswa kwe-aluminium nama-alloys e-aluminium.Ucezu lomsebenzi oluhlanganisiwe kufanele lushiswe ngaphambili ngaphambi kokugqanyiswa ukwenza izinga lokushisa libe seduze nezinga lokushisa lokubhuqa, bese lucwiliswa ku-brazing flux for brazing.Ngesikhathi sokubhula, izinga lokushisa lokubhula kanye nesikhathi sokubhula kufanele kulawulwe ngokuqinile.Uma izinga lokushisa liphezulu kakhulu, isisekelo sensimbi kulula ukuhlakazeka futhi i-solder kulula ukulahleka;Uma izinga lokushisa liphansi kakhulu, i-solder ayincibiliki ngokwanele, futhi izinga lokubhoboza liyancipha.Izinga lokushisa lokubhula lizonqunywa ngokuya ngohlobo nosayizi wesisekelo sensimbi, ukwakheka nendawo yokuncibilika yensimbi yokugcwalisa, futhi ngokuvamile liphakathi kwezinga lokushisa le-liquidus lensimbi yokugcwalisa kanye nezinga lokushisa eliqinile lensimbi eyisisekelo.Isikhathi sokucwilisa i-workpiece ekugezeni kwe-flux kumele siqinisekise ukuthi i-solder ingancibilika ngokugcwele futhi igeleze, futhi isikhathi sokusekela akufanele sibe side kakhulu.Uma kungenjalo, i-elementi ye-silicon ku-solder ingase isakazeke ensimbi eyisisekelo, yenze isisekelo sensimbi eduze komthungo sibe brittle.

Ku-vacuum brazing ye-aluminium nama-alloys e-aluminium, izivuseleli zokusebenza zensimbi zivame ukusetshenziselwa ukuguqula ifilimu ye-oxide engaphezulu ye-aluminium futhi kuqinisekiswe ukumanziswa nokusabalala kwe-solder.I-Magnesium ingasetshenziswa ngokuqondile ku-workpiece ngesimo sezinhlayiya, noma ifakwe endaweni yokubhula ngesimo se-steam, noma i-magnesium ingezwa ku-solder ye-aluminium silicon njenge-alloy element.Okokusebenza okunesakhiwo esiyinkimbinkimbi, ukuze kuqinisekiswe umphumela ogcwele womhwamuko we-magnesium esisekelweni sensimbi futhi uthuthukise ikhwalithi yokubhoda, izinyathelo zenqubo yokuvikela yendawo zivame ukuthathwa, okungukuthi, ucezu lokusebenzela lufakwa kuqala ebhokisini lensimbi engagqwali (ngokuvamile. elaziwa njengebhokisi lenqubo), bese lifakwa esithandweni se-vacuum ukuze kushiswe i-brazing.I-Vacuum Brazed Aluminium kanye namajoyinti e-aluminium alloy anendawo ebushelelezi namalunga aminyene brazed, futhi awadingi ukuhlanzwa ngemva kokubhula;Kodwa-ke, okokusebenza kwe-vacuum brazing kuyabiza, futhi umhwamuko we-magnesium ungcolisa isithando somlilo, ngakho-ke udinga ukuhlanzwa futhi unakekelwe njalo.

Uma i-aluminiyamu ebhula ngengxubevange ye-aluminium endaweni engathathi hlangothi noma engasebenzi, i-activator ye-magnesium noma i-flux ingasetshenziswa ukususa ifilimu.Uma i-activator ye-magnesium isetshenziselwa ukususa ifilimu, inani le-magnesium elidingekayo liphansi kakhulu kunalelo lokubhula kwe-vacuum.Ngokuvamile, u-w (mg) cishe u-0.2% ~ 0.5%.Lapho okuqukethwe kwe-magnesium kuphezulu, ikhwalithi yokuhlangana izoncishiswa.I-NOCOLOK brazing indlela esebenzisa i-fluoride flux nokuvikela i-nitrogen iyindlela entsha ethuthukiswe ngokushesha eminyakeni yamuva.Njengoba insalela ye-fluoride flux ingamumbi umswakama futhi ingagqwali ku-aluminium, inqubo yokususa izinsalela ze-flux ngemva kokubhula ingashiywa.Ngaphansi kokuvikelwa kwe-nitrogen, inani elincane kuphela le-fluoride flux elidinga ukumbozwa, insimbi yokugcwalisa ingakwazi ukumanzisa kahle isisekelo sensimbi, futhi kulula ukuthola amalunga aphezulu e-brazed.Njengamanje, le ndlela yokubhula ye-NOCOLOK isetshenziswe ekukhiqizeni i-aluminium radiator nezinye izingxenye.

Okwe-aluminiyamu ne-aluminiyamu ingxubevange eboshwe nge-flux ngaphandle kwe-fluoride flux, insalela ye-flux kufanele isuswe ngokuphelele ngemva kokubhula.Insalela ye-organic brazing flux ye-aluminium ingagezwa ngezixazululo eziphilayo ezifana ne-methanol ne-trichlorethylene, ingathathi hlangothi nge-sodium hydroxide aqueous solution, futhi ekugcineni ihlanzwe ngamanzi ashisayo nabandayo.I-chloride iyinsalela ye-brazing flux ye-aluminium, engasuswa ngokuvumelana nezindlela ezilandelayo;Okokuqala, cwilisa emanzini ashisayo ku-60 ~ 80 ℃ i-10min, uhlanze ngokucophelela insalela ekuhlanganyeleni kwe-brazed ngebhulashi, futhi uyihlanze ngamanzi abandayo;Bese uyicwilisa ku-15% we-nitric acid aqueous solution for 30min, bese ekugcineni uyihlanza ngamanzi abandayo.

Isikhathi sokuthumela: Jun-13-2022