1. I-brazing material

(1)I-Brazing ye-carbon steel kanye ne-low alloy steel ihlanganisa i-soft brazing kanye ne-hard brazing.I-solder esetshenziswa kabanzi ekufakweni okuthambile i-tin lead solder.Ukumanzisa kwalesi solder kuya ensimbi kuyanda ngokwanda kokuqukethwe kwe-tin, ngakho-ke i-solder enokuqukethwe okuphezulu kwe-tin kufanele isetshenziselwe ukuhlanganisa amalunga.I-Fesn2 intermetallic compound layer ingase yakheke esibonakalayo phakathi kwethayela nensimbi kuthayela lomthofu.Ukuze ugweme ukwakheka kwe-compound kulolu ungqimba, izinga lokushisa lokubilisa kanye nesikhathi sokubamba kufanele kulawulwe kahle.Amandla okugunda amajoyinti ensimbi ekhabhoni aboshwe ngamasolda omthofu ambalwa ajwayelekile aboniswa kuThebula 1. Phakathi kwawo, amandla ahlangene ahlanganiswe ngo-50% w (SN) aphakeme kakhulu, futhi amandla ahlangene ashiselwe nge-antimony free solder angaphezulu ukuthi nge-antimony.

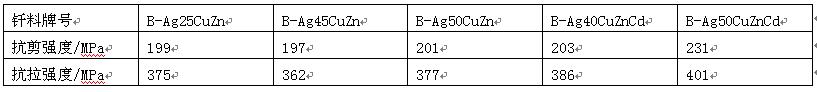

Ithebula 1 lamandla okugunda amajoyinti ensimbi ekhabhoni aboshwe ngesoda yomthofu kathayela

Lapho kufakwa insimbi ye-carbon steel nensimbi ephansi ye-alloy, ithusi elimsulwa, i-zinc yethusi kanye nezinsimbi zethusi ze-zinc brazing filler zisetshenziswa kakhulu.Ithusi elihlanzekile linendawo ephezulu yokuncibilika futhi kulula ukwenza i-oxidize isisekelo sensimbi ngesikhathi sokubhula.Isetshenziswa kakhulu ukubhula ngegesi okuvikelwe kanye ne-vacuum brazing.Kodwa-ke, kufanele kuqashelwe ukuthi igebe phakathi kwamalunga ahlanganisiwe kufanele libe ngaphansi kuka-0.05mm ukuze kugwenywe inkinga yokuthi igebe elihlangene alikwazi ukugcwaliswa ngenxa yokugeleza okuhle kwethusi.I-carbon steel kanye namajoyinti ensimbi ye-alloy ephansi aboshwe ngethusi elihlanzekile anamandla aphezulu.Ngokuvamile, amandla okugunda angu-150 ~ 215mpa, kuyilapho amandla aqinile asakazwa phakathi kuka-170 ~ 340mpa.

Uma kuqhathaniswa nethusi elimsulwa, indawo yokuncibilika ye-zinc solder yethusi iyancipha ngenxa yokwengezwa kwe-Zn.Ukuze uvimbele ukuhwamuka kwe-Zn ngesikhathi sokubhula, ngakolunye uhlangothi, inani elincane le-Si lingangezwa ku-solder yethusi ye-zinc;Ngakolunye uhlangothi, izindlela zokushisisa ngokushesha kufanele zisetshenziswe, njengokugqamisa amalangabi, i-induction brazing kanye ne-dip brazing.Amalungu ensimbi ye-carbon steel nensimbi ephansi ye-alloy brazed nge-copper zinc filler metal anamandla amahle kanye nepulasitiki.Isibonelo, amandla aqinile namandla okugunda amajoyinti ensimbi ye-carbon brazed nge-b-cu62zn solder afinyelela ku-420MPa no-290mpa.Iphuzu elincibilikayo le-solder yesiteshi sethusi sesiliva liphansi kunalelo le-zinc solder yethusi, elilungele ukushiselwa inaliti.Le nsimbi yokugcwalisa ifanele ukuvutha komlilo, i-induction brazing kanye nokushisa kwesithando somlilo we-carbon steel kanye nensimbi ephansi ye-alloy, kodwa okuqukethwe kwe-Zn kufanele kuncishiswe ngangokunokwenzeka ngesikhathi sokushisa kwesithando somlilo, futhi izinga lokushisa kufanele lenyuke.I-Brazing carbon steel kanye nensimbi ephansi ye-alloy enensimbi yokugcwalisa i-zinc yesiliva ingathola amalunga anamandla amahle kanye nepulasitiki.Idatha ethile ibalwe kuThebula 2.

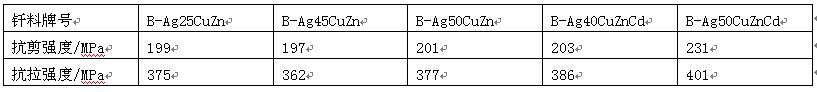

Amandla ethebula 2 amajoyinti ensimbi ekhabhoni ephansi aboshwe ngesoda ye-zinc yethusi esiliva

(2) I-Flux: i-flux noma igesi evikelayo izosetshenziselwa ukubhula insimbi ye-carbon steel ne-low alloy steel.I-flux ivame ukunqunywa yinsimbi yokugcwalisa ekhethiwe kanye nendlela yokufaka.Lapho kusetshenziswa i-tin lead solder, uketshezi oluxubile lwe-zinc chloride ne-ammonium chloride lungasetshenziswa njenge-flux noma enye i-flux ekhethekile.Okusele kwalokhu kuguquguquka kuvame ukugqwala kakhulu, futhi ilunga kufanele lihlanzwe ngokuqinile ngemva kokubhuqa.

Lapho kubhukwa ngensimbi yokugcwalisa i-zinc, kuzokhethwa i-fb301 noma i-fb302 flux, okungukuthi, i-borax noma ingxube ye-borax ne-boric acid;Ekubaseni ilangabi, ingxube ye-methyl borate ne-formic acid ingasetshenziswa njenge-brazing flux, lapho umhwamuko we-B2O3 udlala indima yokususwa kwefilimu.

Lapho kusetshenziswa insimbi yokugcwalisa i-zinc yesiliva yethusi, i-fb102, fb103 kanye ne-fb104 brazing fluxes ingakhethwa, okungukuthi, ingxube ye-borax, i-boric acid namanye ama-fluoride.Okusele kwalokhu kuguquguquka kugqwala ngezinga elithile futhi kufanele kususwe ngemva kokubhuqa.

2. Ubuchwepheshe be-Brazing

Ingaphezulu elizoshiselwa kufanele lihlanzwe ngezindlela zemishini noma zamakhemikhali ukuze kuqinisekiswe ukuthi ifilimu ye-oxide ne-organic matter kususwa ngokuphelele.Indawo ehlanjululiwe akumele ibe mahhadlahhadla futhi akufanele inamathele kuma-chips ensimbi noma okunye ukungcola.

Insimbi ye-Carbon kanye nensimbi ephansi ye-alloy ingafakwa nge-brazed ngezindlela ezihlukahlukene ezijwayelekile zokubhula.Ngesikhathi sokushisa amalangabi, ilangabi elingathathi hlangothi noma elinciphisa kancane kufanele lisetshenziswe.Ngesikhathi sokusebenza, ukushisa okuqondile kwe-filler metal kanye ne-flux ngelangabi kufanele kugwenywe ngangokunokwenzeka.Izindlela zokushisa ezisheshayo ezifana nokufaka i-induction brazing kanye ne-dip brazing zifaneleka kakhulu ukubethelwa kwensimbi ecishiwe nepholile.Ngesikhathi esifanayo, ukucisha noma ukugqama endaweni yokushisa ephansi kune-temering kufanele kukhethwe ukuvimbela ukuthambisa kwesisekelo sensimbi.Lapho ubhula insimbi ephansi ye-alloy enamandla aphezulu emkhathini ovikelayo, akudingekile kuphela ukuhlanzeka okuphezulu kwegesi, kodwa futhi kufanele kusetshenziselwe ukugeleza kwegesi ukuze kuqinisekiswe ukumanziswa nokusabalalisa kwensimbi yokugcwalisa ebusweni bensimbi eyisisekelo.

I-flux eyinsalela ingasuswa ngezindlela zamakhemikhali noma zemishini.Izinsalela ze-organic brazing flux zingasulwa noma zihlanzwe ngophethiloli, utshwala, i-acetone nezinye izinyibilikisi eziphilayo;Izinsalela ze-flux egqwalayo eqinile njenge-zinc chloride ne-ammonium chloride kufanele zisuswe ku-NaOH ingxube yamanzi kuqala, bese ihlanzwa ngamanzi ashisayo nabandayo;Izinsalela ze-boric acid ne-boric acid flux zinzima ukususa, futhi zingaxazululwa kuphela ngezindlela zemishini noma ukucwiliswa isikhathi eside emanzini akhuphukayo.

Isikhathi sokuthumela: Jun-13-2022