1. Solder

Zonke izinhlobo zama-solder ezinezinga lokushisa elingaphansi kuka-3000 ℃ zingasetshenziselwa i-W brazing, futhi ama-solder asekelwe ethusi noma esiliva angasetshenziselwa izingxenye ezinezinga lokushisa elingaphansi kuka-400 ℃;Igolide esekwe, i-manganese esekelwe, i-manganese esekelwe, i-palladium esekelwe noma i-drill based filler metals ngokuvamile isetshenziselwa izingxenye ezisetshenziswa phakathi kuka-400 ℃ no-900 ℃;Ezingxenyeni ezisetshenziswa ngaphezu kuka-1000 ℃, izinsimbi ezihlanzekile ezifana ne-Nb, Ta, Ni, Pt, PD kanye ne-Mo zisetshenziswa kakhulu.Izinga lokushisa elisebenzayo lezingxenye eziboshwe nge-platinum base solder selifinyelele ku-2150 ℃.Uma ukwelashwa kokusabalalisa okungu-1080 ℃ kwenziwa ngemva kokubhula, izinga lokushisa eliphakeme lokusebenza lingafinyelela ku-3038 ℃.

Ama-solder amaningi asetshenziselwa ukubhula w angasetshenziselwa ukubhula i-Mo, futhi ama-solder asekelwe ethusi noma esiliva angasetshenziselwa izingxenye ze-Mo ezisebenza ngaphansi kuka-400 ℃;Okwemishini kagesi kanye nezingxenye ezingezona ezakhiwe ezisebenza ku-400 ~ 650 ℃, ama-Cu Ag, Au Ni, PD Ni noma ama-Cu Ni solders angasetshenziswa;I-Titanium esekelwe noma ezinye izinsimbi ezihlanzekile zokugcwalisa insimbi ezinamaphoyinti aphezulu okuncibilika zingasetshenziselwa izingxenye ezisebenza emazingeni okushisa aphezulu.Kufanele kuqashelwe ukuthi i-manganese esekelwe, i-cobalt esekelwe ku-cobalt kanye nezinsimbi zokugcwalisa ezisekelwe ku-nickel ngokuvamile azinconywa ukuze kugwenywe ukwakheka kwenhlanganisela ye-brittle intermetallic kumalunga okubrazing.

Uma izingxenye ze-TA noma ze-Nb zisetshenziswa ngaphansi kwe-1000 ℃, imijovo esekelwe ethusi, esekelwe ku-manganese, i-cobalt esekelwe, i-titanium esekelwe, i-nickel esekelwe, i-golide esekelwe kanye nemijovo esekelwe palladium ingakhethwa, kuhlanganise ne-Cu Au, i-Au Ni, i-PD Ni ne-Pt Au_ Ni kanye Ama-Cu Sn solders anokumanzisa okuhle ku-TA ne-Nb, ukwakheka okuhle kwe-brazing seam namandla ahlangene aphezulu.Njengoba izinsimbi zokugcwalisa ezisekelwe esiliva zivame ukwenza izinsimbi ezigaqayo zibe brittle, kufanele zigwenywe ngangokunokwenzeka.Ezingxenyeni ezisetshenziswa phakathi kuka-1000 ℃ kanye no-1300 ℃, izinsimbi ezihlanzekile i-Ti, V, Zr noma ama-alloys asekelwe kulezi zinsimbi ezakha okuqinile okungapheli kanye noketshezi ngazo zizokhethwa njengezinsimbi zokugcwalisa.Lapho izinga lokushisa lesevisi liphakeme, insimbi yokugcwalisa equkethe i-HF ingakhethwa.

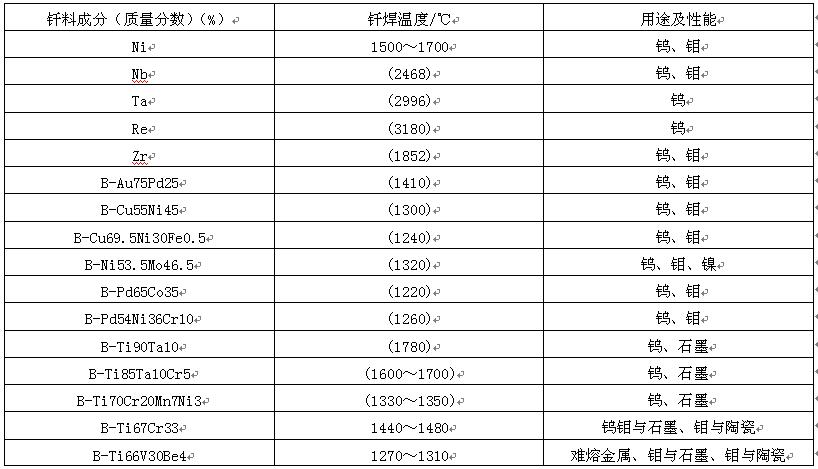

W. Bheka ithebula 13 ukuze uthole izinsimbi zokugcwalisa ze-Mo, Ta kanye ne-Nb ezingeni lokushisa eliphezulu.

Ithebula le-13 lensimbi yokugcwalisa i-brazing yokushisa okuphezulu kwe-brazing yezinsimbi eziphikisayo

Ngaphambi kokubopha, kuyadingeka ukususa ngokucophelela i-oxide ebusweni bensimbi ephikisayo.Ukugaya ngomshini, ukuqhunyiswa kwesihlabathi, ukuhlanza nge-ultrasonic noma ukuhlanza amakhemikhali kungasetshenziswa.I-brazing izokwenziwa ngokushesha ngemva kwenqubo yokuhlanza.

Ngenxa yokonakala okungokwemvelo kwe-W, izingxenye ze-w zizophathwa ngokucophelela emsebenzini wokuhlanganisa ingxenye ukuze kugwenywe ukuphuka.Ukuze uvimbele ukwakheka kwe-brittle tungsten carbide, ukuxhumana okuqondile phakathi kwe-W ne-graphite kufanele kugwenywe.Ukucindezela ngenxa yokucubungula kwangaphambili kwe-welding noma ukushisela kuzoqedwa ngaphambi kokushisela.U-W kulula kakhulu uku-oxidize lapho izinga lokushisa likhuphuka.Idigri ye-vacuum izoba phezulu ngokwanele ngesikhathi sokubhula.Lapho i-brazing yenziwa ngaphakathi kwezinga lokushisa lika-1000 ~ 1400 ℃, i-vacuum degree akufanele ibe ngaphansi kuka-8 × 10-3Pa. Ukuze kuthuthukiswe izinga lokushisa elincibilikayo kanye nokushisa kwesevisi kokuhlangene, inqubo yokufaka ingahlanganiswa ukwelashwa kokusabalalisa ngemuva kokushisela.Isibonelo, i-b-ni68cr20si10fel solder isetshenziselwa ukuqinisa i-W ku-1180 ℃.Ngemuva kokwelashwa okuphindwe kathathu okungu-1070 ℃ /4h, 1200 ℃/3.5h no-1300 ℃/2h ngemva kokushisela, izinga lokushisa lesevisi le-brazed joint lingafinyelela ngaphezu kuka-2200 ℃.

I-coefficient encane yokunwetshwa kwe-thermal kufanele inakwe lapho kuhlanganiswa i-joint brazed ye-Mo, futhi igebe elihlangene kufanele libe phakathi kwebanga elingu-0.05 ~ 0.13MM.Uma i-fixture isetshenziswa, khetha into ene-coefficient encane yokunwetshwa kwe-thermal.I-Mo recrystallization yenzeka lapho ukugqama kwelangabi, isithando somlilo esilawulwayo, isithando somlilo se-vacuum, isithando somlilo esingeniswayo kanye nokushisa kokumelana kudlula izinga lokushisa le-recrystallization noma izinga lokushisa le-recrystallization lehla ngenxa yokusabalalisa izakhi ze-solder.Ngakho-ke, lapho izinga lokushisa elikhazimulayo liseduze nezinga lokushisa le-recrystallization, isikhathi sokushisa sifushane, singcono.Uma icwebezela ngaphezu kwezinga lokushisa elikhazimulayo le-Mo, isikhathi sokubhuqa nezinga lokupholisa kufanele kulawulwe ukugwema ukuqhekeka okubangelwa ukupholisa okusheshayo.Lapho kusetshenziswa i-oxyacetylene flame brazing, kuhle ukusebenzisa i-mix flux, okungukuthi, i-industrial borate noma i-silver brazing flux kanye ne-high-temperature flux ene-calcium fluoride, engathola ukuvikeleka okuhle.Indlela iwukuba uqale ugqoke ungqimba lwesiliva ecwebezelayo ebusweni be-Mo, bese umboza ukuguquguquka kwezinga lokushisa eliphezulu.I-silver brazing flux inomsebenzi ebangeni lokushisa eliphansi, futhi izinga lokushisa elisebenzayo le-high-temperature flux lingafinyelela ku-1427 ℃.

Izingxenye ze-TA noma ze-Nb zikhethwa ukuba ziboshwe ngaphansi kwe-vacuum, futhi idigri ye-vacuum ayikho ngaphansi kuka-1.33 × 10-2Pa.Uma i-brazing yenziwa ngaphansi kokuvikelwa kwegesi ye-inert, ukungcola kwegesi okufana ne-carbon monoxide, ammonia, i-nitrogen ne-carbon dioxide kufanele kususwe ngokuqinile.Lapho i-brazing brazing noma ukumelana nokwenziwa emoyeni, insimbi ekhethekile yokugcwalisa i-brazing kanye ne-flux efanele izosetshenziswa.Ukuze uvimbele i-TA noma i-Nb ukuthi ixhumane nomoya-mpilo kumazinga okushisa aphezulu, ungqimba lwe-metallic yethusi noma i-nickel lungagqitshwa phezulu futhi ukwelashwa okuhambisanayo kwe-annealing kungenziwa.

Isikhathi sokuthumela: Jun-13-2022