Ukushisa kwe-Superalloys

(1) Izici ze-Brazing superalloy zingahlukaniswa zibe izigaba ezintathu: isisekelo se-nickel, isisekelo sensimbi nesisekelo se-cobalt. Zinezici ezinhle zemishini, ukumelana ne-oxidation kanye nokumelana nokugqwala emazingeni okushisa aphezulu. I-nickel base alloy isetshenziswa kabanzi ekukhiqizeni okusebenzayo.

I-superalloy iqukethe i-Cr eyengeziwe, nefilimu ye-Cr2O3 oxide okunzima ukuyisusa yakheka phezulu ngesikhathi sokushisisa. Ama-superalloy esisekelo se-nickel aqukethe i-Al ne-Ti, okulula ukuyikhipha nge-oxidize uma ishiswa. Ngakho-ke, ukuvimbela noma ukunciphisa i-oxidation yama-superalloys ngesikhathi sokushisa nokususa ifilimu ye-oxide kuyinkinga eyinhloko ngesikhathi sokubhoboza. Njengoba i-borax noma i-boric acid ekuguquguqukeni ingabangela ukugqwala kwesisekelo sensimbi ekushiseni kwe-brazing, i-boron eya phezulu ngemva kokusabela ingangena kusisekelo sensimbi, okuholela ekungeneni kwe-intergranular. Kuma-alloys esisekelo se-nickel anokuqukethwe okuphezulu kwe-Al ne-Ti, idigri ye-vacuum esimweni esishisayo akufanele ibe ngaphansi kuka-10-2 ~ 10-3pa ngesikhathi sokubhula ukuze kugwenywe i-oxidation endaweni eyingxubevange ngesikhathi sokushisisa.

Ukuze isixazululo siqiniswe futhi imvula iqiniswe ama-alloys esisekelo se-nickel, izinga lokushisa lokubilisa kufanele lihambisane nezinga lokushisa lokushisa lokwelashwa kwesixazululo ukuze kuqinisekiswe ukuqedwa okugcwele kwezakhi ze-alloy. Ukushisa kwe-brazing kuphansi kakhulu, futhi izakhi ze-alloy azikwazi ukuqedwa ngokuphelele; Uma izinga lokushisa lokushisa liphezulu kakhulu, okusanhlamvu kwensimbi okuyisisekelo kuzokhula, futhi izakhiwo zezinto ezibonakalayo ngeke zibuyiselwe ngisho nangemva kokwelashwa kokushisa. Izinga lokushisa eliqinile lesisombululo se-cast base alloys liphezulu, ngokuvamile elingeke lithinte izakhiwo zezinto ngenxa yezinga lokushisa eliphakeme kakhulu lokubhuqa.

Amanye ama-superalloy ase-nickel base, ikakhulukazi imvula eqinisiwe ama-alloys, anomkhuba wokuqhekeka kwengcindezi. Ngaphambi kokugcoba, ukucindezeleka okwenziwe kule nqubo kufanele kususwe ngokugcwele, futhi ukucindezeleka okushisayo kufanele kuncishiswe ngesikhathi sokubhoboza.

(2) Ingxubevange ye-nickel base alloy ingafakwa ngensimbi, ithusi elimsulwa, isisekelo se-nickel kanye ne-solder esebenzayo. Lapho izinga lokushisa elisebenzayo lokuhlangana lingephezulu, izinto ezisekelwe esiliva zingasetshenziswa. Kunezinhlobo eziningi zama-solder asekelwe esiliva. Ukuze unciphise ukucindezeleka kwangaphakathi ngesikhathi sokushisa kwe-brazing, kungcono ukukhetha i-solder enokushisa okuncibilika okuphansi. I-Fb101 flux ingasetshenziselwa ukuqinisa ngensimbi yokugcwalisa isisekelo sesiliva. I-Fb102 flux isetshenziselwa imvula eqinile eqinile enokuqukethwe okuphezulu kwe-aluminium, futhi i-10% ~ 20% ye-sodium silicate noma i-aluminium flux (efana ne-fb201) iyengezwa. Uma izinga lokushisa lokubeka lingaphezu kuka-900 ℃, kuzokhethwa i-fb105 flux.

Uma ubhebheza ku-vacuum noma emkhathini ovikelayo, ithusi elihlanzekile lingasetshenziswa njengensimbi yokugcwalisa. Ukushisa kwe-brazing kungu-1100 ~ 1150 ℃, futhi ukujoyina ngeke kukhiqize ukuqhekeka kwengcindezi, kodwa izinga lokushisa lokusebenza akufanele lidlule ku-400 ℃.

I-nickel base brazing filler metal iyinsimbi yokugcwalisa evame ukusetshenziswa kakhulu kumaSuperalloys ngenxa yokusebenza kwayo okuhle kwezinga lokushisa eliphezulu futhi akukho ukuqhekeka kwengcindezi ngesikhathi sokubhula. Izakhi eziyinhloko ze-alloy ku-nickel base solder ziyi-Cr, Si, B, kanye nenani elincane le-solder liqukethe i-Fe, W, njll. Uma kuqhathaniswa ne-ni-cr-si-b, i-b-ni68crwb brazing filler metal inganciphisa ukungena kwe-intergranular B esisekelweni sensimbi futhi kwandise isikhathi sokuncibilika kwezinga lokushisa. Kuyinsimbi yokugcwalisa ecwebezelayo yokufaka izingxenye ezisebenzayo ezisezingeni eliphezulu nezinsimbi ze-turbine. Kodwa-ke, i-fluidity ye-solder equkethe i-W iba yimbi kakhulu futhi igebe elihlangene linzima ukulawula.

I-diffusion brazing filler metal esebenzayo ayiqukethe i-Si element futhi inokumelana ne-oxidation okuhle kakhulu kanye nokumelana ne-vulcanization. Ukushisa kwe-brazing kungakhethwa kusuka ku-1150 ℃ kuya ku-1218 ℃ ngokusho kohlobo lwe-solder. Ngemuva kokubhula, i-brazed joint enezakhiwo ezifanayo nesisekelo sensimbi ingatholakala ngemuva kokwelashwa kokusabalalisa okungu-1066 ℃.

(3) I-brazing inqubo ye-nickel base alloy ingasebenzisa ukugqama esithandweni somlilo esivikelayo, i-vacuum brazing kanye noxhumo lwesigaba soketshezi lwesikhashana. Ngaphambi kokugqama, indawo engaphezulu kufanele isuswe amafutha futhi ikhishwe i-oxide ngokupholisha i-sandpaper, ukupholishwa kwamasondo okuzwakele, ukukhuhla i-acetone nokuhlanza amakhemikhali. Uma ukhetha amapharamitha wenqubo ye-brazing, kufanele kuqashelwe ukuthi izinga lokushisa lokushisa akufanele libe phezulu kakhulu futhi isikhathi sokubhula kufanele sibe sifushane ukuze kugwenywe ukusabela kwamakhemikhali okunamandla phakathi kwe-flux nesisekelo sensimbi. Ukuze uvimbele isisekelo sensimbi ekuqhekekeni, izingxenye ezicutshunguliwe ezibandayo zizokhululeka ngaphambi kokushisela, futhi ukushisisa kwe-welding kufanele kube okufanayo ngangokunokwenzeka. Ukuze kube nemvula eqinisiwe ama-superalloy, izingxenye kufanele zibhekane nokwelashwa kwesisombululo esiqinile kuqala, bese zifakwa ngaphansi kwezinga lokushisa elingaphezudlwana kokwelashwa kokuqinisa ukuguga, futhi ekugcineni ukwelashwa kokuguga.

I-1) Ukushisa endaweni yokuvikela isithando somlilo esivuthayo esithandweni somoya esivikelayo kudinga ukuhlanzeka okuphezulu kwegesi evikelayo. Kuma-superalloy ano-w (AL) kanye no-w (TI) ngaphansi kuka-0.5%, indawo yamazolo izoba ngaphansi kuka -54 ℃ uma kusetshenziswa i-hydrogen noma i-argon. Uma okuqukethwe kwe-Al ne-Ti kwanda, i-alloy surface isakhipha i-oxidize uma ishiswa. Kufanele kuthathwe izinyathelo ezilandelayo; Engeza inani elincane le-flux (njenge-fb105) bese ususa ifilimu ye-oxide nge-flux; 0.025 ~ 0.038mm uqweqwe oluwugqinsi lubekwe phezu kwezingxenye; Fafaza i-solder ebusweni bezinto okufanele ziboshwe kusengaphambili; Engeza inani elincane lokugeleza kwegesi, njenge-boron trifluoride.

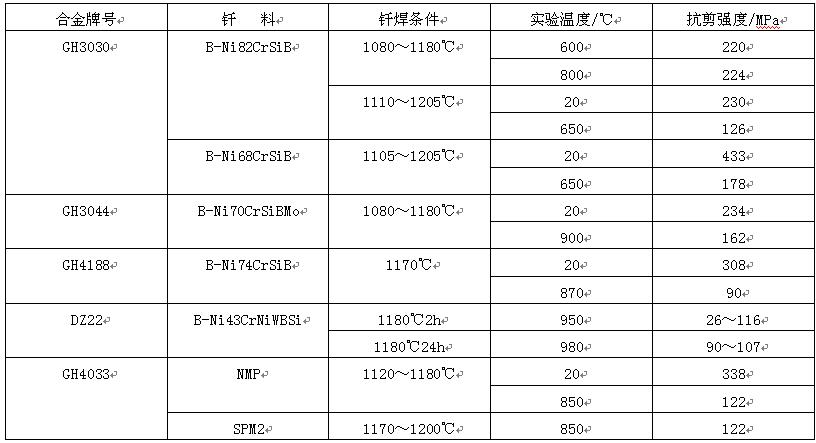

2) I-vacuum brazing vacuum brazing isetshenziswa kabanzi ukuthola umphumela ongcono wokuvikela kanye nekhwalithi yokubhuqa. Bheka ithebula 15 mayelana nezakhiwo zemishini zamajoyinti e-nickel base superalloy ajwayelekile. Kuma-superalloys ano-w (AL) no-w (TI) ngaphansi kuka-4%, kungcono ukufaka i-electroplate ungqimba lwe-nickel engu-0.01 ~ 0.015mm ngaphezulu, nakuba ukumanziswa kwe-solder kungaqinisekiswa ngaphandle kokwelashwa okukhethekile. Uma i-w (AL) kanye ne-w (TI) idlula u-4%, ubukhulu be-nickel coating buzoba ngu-0.020.03mm. Ukugqoka okuncane kakhulu akunawo umphumela wokuvikela, futhi ukugqoka okuminyene kakhulu kuzonciphisa amandla okuhlangana. Izingxenye ezizoshiselwa zingafakwa futhi ebhokisini ukuze kufakwe i-vacuum brazing. Ibhokisi kufanele ligcwaliswe nge-getter. Isibonelo, i-Zr idonsa igesi ekushiseni okuphezulu, okungakha i-vacuum yendawo ebhokisini, ngaleyo ndlela ivimbele i-oxidation ye-alloy surface.

Ithebula 15 izakhiwo zemishini ze-Vacuum Brazed Joints of ejwayelekile nickel base superalloy

I-microstructure namandla wejoyinti eliqinile le-Superalloy lishintsha ngegebe lokubraziza, kanye nokwelashwa kokusabalalisa ngemva kokubhula kuzothuthukisa inani eliphakeme elivunyelwe legebe elihlanganyelwe. Uma sithatha i-Inconel alloy njengesibonelo, igebe eliphezulu le-Inconel joint brazed ne-b-ni82crsib lingafinyelela ku-90um ngemva kokwelashwa kokusabalalisa ku-1000 ℃ ku-1H; Kodwa-ke, kumalunga aboshwe nge-b-ni71crsib, igebe eliphezulu lingaba ngu-50um ngemva kokwelashwa kokusabalalisa ku-1000 ℃ ku-1H.

3) Uxhumano lwesigaba soketshezi lwesikhashana Uxhumano lwesigaba soketshezi oludlulayo lusebenzisa ingxubevange ye-interlayer (cishe u-2.5 ~ 100um obukhulu) indawo yayo yokuncibilika iphansi kunesisekelo sensimbi njengensimbi yokugcwalisa. Ngaphansi kwengcindezi encane (0 ~ 0.007mpa) kanye nezinga lokushisa elifanele (1100 ~ 1250 ℃), impahla ye-interlayer kuqala iyancibilika futhi imanzise isisekelo sensimbi. Ngenxa yokusakazeka ngokushesha kwezakhi, ukuqiniswa kwe-isothermal kwenzeka endaweni ehlangene ukuze kwakheke ilunga. Le ndlela inciphisa kakhulu izidingo ezihambisanayo ze-base metal surface futhi inciphisa ingcindezi yokushisela. Imingcele eyinhloko yokuxhuma kwesigaba se-liquid esikhashana ingcindezi, izinga lokushisa, isikhathi sokubamba kanye nokwakheka kwe-interlayer. Faka ingcindezi encane ukuze ugcine indawo yokukhwelana ye-weld ixhumene kahle. Ukushisa kokushisa nesikhathi kunomthelela omkhulu ekusebenzeni kokujoyina. Uma okuhlangene kudingeka ukuthi kuqine njengensimbi eyisisekelo futhi kungaphazamisi ukusebenza kwesisekelo sensimbi, imingcele yenqubo yokuxhuma yokushisa okuphezulu (okufana no-≥ 1150 ℃) kanye nesikhathi eside (njenge-8 ~ 24h) izokwamukelwa; Uma ikhwalithi yokuxhuma ye-joint iyancipha noma isisekelo sensimbi singakwazi ukumelana nokushisa okuphezulu, izinga lokushisa eliphansi (1100 ~ 1150 ℃) kanye nesikhathi esifushane (1 ~ 8h) sizosetshenziswa. Isendlalelo esimaphakathi sizothatha ukwakheka kwensimbi eyisisekelo exhunyiwe njengokwakheka okuyisisekelo, futhi sengeze izakhi zokupholisa ezihlukene, ezifana ne-B, Si, Mn, Nb, njll. Isibonelo, ukwakheka kwe-Udimet alloy yi-ni-15cr-18.5co-4.3al-3.3ti-5mo, futhi ukwakheka kwesendlalelo esimaphakathi sokuxhunywa kwesigaba soketshezi lwesikhashana yi-b-55.5162. Zonke lezi zakhi zingehlisa izinga lokushisa elincibilikayo lama-alloys e-Ni Cr noma e-Ni Cr Co libe phansi kakhulu, kodwa umphumela we-B yiwona osobala kakhulu. Ngaphezu kwalokho, izinga eliphezulu lokusabalalisa lika-B lingashintsha ngokushesha ingxubevange ye-interlayer kanye nesisekelo sensimbi.

Isikhathi sokuthumela: Jun-13-2022