Incazelo nenjongo yokucisha

Insimbi ishiselwa ezingeni lokushisa elingaphezu kwephuzu elibalulekile i-Ac3 (insimbi ye-hypoeutectoid) noma i-Ac1 (insimbi ye-hypereutectoid), igcinwa isikhathi esithile ukuze yenziwe i-austenitized ngokugcwele noma ingxenye, bese ipholiswa ngesivinini esikhulu kunesivinini esibucayi sokucisha. Inqubo yokwelapha ukushisa eguqula i-austenite epholile ibe yi-martensite noma i-bainite ephansi ibizwa ngokuthi i-quenching.

Inhloso yokucisha iwukuguqula i-austenite epholile kakhulu ibe i-martensite noma i-bainite ukuze kutholwe i-martensite noma isakhiwo esiphansi se-bainite, esihlanganiswa nokufudumeza kumazinga okushisa ahlukene ukuze kuthuthukiswe kakhulu amandla, ubulukhuni, nokumelana nensimbi. Ukugqokeka, amandla okukhathala kanye nokuqina, njll., ukuhlangabezana nezidingo ezihlukene zokusetshenziswa kwezingxenye ezihlukene zemishini namathuluzi. Ukucisha kungase futhi kusetshenziselwe ukuhlangabezana nezakhiwo ezikhethekile zomzimba namakhemikhali zezinsimbi ezithile ezikhethekile ezifana ne-ferromagnetism kanye nokumelana nokugqwala.

Lapho izingxenye zensimbi zipholiswa endaweni yokucisha ngoshintsho esimweni somzimba, inqubo yokupholisa ngokuvamile ihlukaniswa ibe izigaba ezintathu ezilandelayo: isigaba sefilimu somhwamuko, isigaba sokubilisa, nesiteji sokuhambisa.

Ukuqina kwensimbi

Ukuqina nokuqina yizinkomba ezimbili zokusebenza ezibonisa ikhono lensimbi lokuqeda. Futhi ziyisisekelo esibalulekile sokukhetha nokusetshenziswa kwezinto ezibonakalayo.

1. Imiqondo yokuqina nokuqina

Ukuqina yikhono lensimbi lokufeza ubulukhuni obuphakeme kakhulu engabufinyelela lapho licinywa futhi liqina ngaphansi kwezimo ezifanele. Isici esiyinhloko esinquma ukuqina kwensimbi yi-carbon content yensimbi. Ukunemba kakhudlwana, okuqukethwe kwekhabhoni okuncibilikisiwe ku-austenite ngesikhathi sokucisha nokushisa. Ukuphakama kwekhabhoni, kuyanda ukuqina kwensimbi. . Izakhi ze-alloying ensimbi zinomthelela omncane ekuqineni, kodwa zinomthelela omkhulu ekuqineni kwensimbi.

Ukuqina kubhekisela ezicini ezinquma ukujula kokuqina nokusabalalisa kwensimbi ngaphansi kwezimo ezithile. Okusho ukuthi, ikhono lokuthola ukujula kwesendlalelo esiqinile lapho insimbi icinywa. Kuyimpahla yemvelo yensimbi. Ukuqina empeleni kukhombisa ukunethezeka i-austenite eguquka ngayo ibe i-martensite lapho insimbi icinywa. Ngokuyinhloko ihlobene nokuzinza kwe-austenite ye-supercooled yensimbi, noma izinga lokupholisa elibalulekile lokucisha lensimbi.

Kufanele futhi kuphawulwe ukuthi ukuqina kwensimbi kufanele kuhlukaniswe nokujula kokuqina okusebenzayo kwezingxenye zensimbi ngaphansi kwezimo ezithile zokucisha. Ukuqina kwensimbi kuyimpahla yemvelo yensimbi ngokwayo. Incike kuphela ezintweni zayo zangaphakathi futhi ayihlangene nezici zangaphandle. Ukujula kokuqina kokuqina kwensimbi akuxhomekile nje kuphela ekuqineni kwensimbi, kodwa futhi kuncike ezintweni ezisetshenzisiwe. Ihlobene nezici zangaphandle ezifana nendawo yokupholisa kanye nosayizi wesiqeshana somsebenzi. Isibonelo, ngaphansi kwezimo ezifanayo ze-austenitizing, ukuqina kwensimbi efanayo kuyafana, kodwa ukujula kokuqina okusebenzayo kokucisha amanzi kukhulu kunokokucisha uwoyela, futhi izingxenye ezincane zincane kunokucima uwoyela. Ukujula kokuqina okusebenzayo kwezingxenye ezinkulu kukhulu. Lokhu ngeke kushiwo ukuthi ukucisha amanzi kunokuqina okuphezulu kunokucima uwoyela. Akunakushiwo ukuthi izingxenye ezincane zinokuqina okuphezulu kunezingxenye ezinkulu. Kungabonakala ukuthi ukuhlola ukuqina kwensimbi, ithonya lezici zangaphandle ezifana nokuma kwe-workpiece, usayizi, indawo yokupholisa, njll. kumele kuqedwe.

Ngaphezu kwalokho, njengoba ukuqina nokuqina kuyimiqondo emibili ehlukene, insimbi enobulukhuni obuphezulu ngemva kokucisha ayinakho ukuqina okuphezulu; futhi insimbi enobulukhuni obuphansi ingase ibe nokuqina okuphezulu.

2. Izinto ezithinta ukuqina

Ukuqina kwensimbi kuncike ekuzinzeni kwe-austenite. Noma iyiphi into engathuthukisa ukuzinza kwe-austenite epholile kakhulu, isuse ijika elingu-C iye kwesokudla, futhi ngaleyo ndlela inciphise izinga lokupholisa elibalulekile ingathuthukisa ukuqina kwensimbi ephezulu. Ukuzinza kwe-austenite ikakhulukazi kuncike ekwakhekeni kwamakhemikhali, usayizi wokusanhlamvu kanye nokufana kokwakheka, okuhlobene nokwakheka kwamakhemikhali ensimbi nezimo zokushisa.

3.Indlela yokulinganisa yokuqina

Ziningi izindlela zokukala ukuqina kwensimbi, ezisetshenziswa kakhulu indlela yokulinganisa ububanzi obubucayi kanye nendlela yokuhlola ukuqina kokuphela.

(1)Indlela yokulinganisa i-diameter ebalulekile

Ngemuva kokuthi insimbi icinywe endaweni ethile, ububanzi obukhulu lapho ingqikithi ithola yonke i-martensite noma i-50% yesakhiwo se-martensite ibizwa ngokuthi ububanzi obubucayi, obumelwe nguDc. Indlela yokulinganisa i-diameter ebalulekile iwukwenza uchungechunge lwezinduku eziyindilinga ezinobubanzi obuhlukene, futhi ngemva kokucisha, linganisa ubulukhuni bejika lika-U elisakazwa ngobubanzi engxenyeni ngayinye yesampula, futhi uthole induku enesakhiwo se-semi-martensite phakathi nendawo. Ububanzi benduku eyindilinga Yilokho ububanzi obubucayi. Ubukhulu be-diameter ebaluleke kakhulu, buphakama ukuqina kwensimbi.

(2) Qeda indlela yokuhlola yokucisha

Indlela yokuhlola yokuphelisa isebenzisa usayizi ojwayelekile ocisha isifanekiso (Ф25mm×100mm). Ngemva kwe-austenitization, amanzi afafazwa engxenyeni eyodwa yesifanekiso emshinini okhethekile ukuze apholise. Ngemuva kokupholisa, ukuqina kukalwa ngokuhambisana nesiqondiso se-axis - kusukela ekugcineni okupholiswe ngamanzi. Indlela yokuhlola yejika lobudlelwano bebanga. Indlela yokuhlola ukuqina kokuphela ingenye yezindlela zokunquma ukuqina kwensimbi. Izinzuzo zayo ukusebenza okulula kanye nobubanzi besicelo esibanzi.

4.Ukucisha ukucindezeleka, ukuguqulwa nokuqhekeka

(1) Ukucindezeleka kwangaphakathi kwe-workpiece ngesikhathi sokucisha

Lapho i-workpiece ipholiswa ngokushesha endaweni yokucisha, njengoba i-workpiece inobukhulu obuthile futhi i-coefficient conductivity eshisayo nayo iyinani elithile, i-gradient ethile yokushisa izokwenzeka eduze kwesigaba sangaphakathi somsebenzi ngesikhathi sokupholisa. Izinga lokushisa elingaphezulu liphansi, izinga lokushisa elingumongo liphezulu, futhi izinga lokushisa elingaphezulu kanye nengqikithi liphezulu. Kukhona umehluko wezinga lokushisa. Phakathi nenqubo yokupholisa ye-workpiece, kukhona futhi izenzakalo ezimbili ezibonakalayo: enye ukukhuliswa okushisayo, njengoba izinga lokushisa lehla, ubude bomugqa we-workpiece buzoncipha; enye inguquko ye-austenite ku-martensite lapho izinga lokushisa lehla endaweni yokuguqulwa kwe-martensite. , okuzokwandisa ivolumu ethile. Ngenxa yomehluko wokushisa phakathi nenqubo yokupholisa, inani lokunwetshwa kokushisa lizohluka ezingxenyeni ezihlukene eduze kwesigaba sesiphambano se-workpiece, futhi ukucindezeleka kwangaphakathi kuzokwenziwa ezingxenyeni ezihlukene ze-workpiece. Ngenxa yokuba khona kokuhluka kwezinga lokushisa ngaphakathi kwendawo yokusebenza, kungase kube nezingxenye lapho izinga lokushisa lehla ngokushesha kunephuzu lapho kwenzeka khona i-martensite. Ukuguqulwa, umthamo uyakhula, futhi izingxenye ezinokushisa okuphezulu zisaphakeme kunephuzu futhi zisesimeni se-austenite. Lezi zingxenye ezihlukene zizophinde zikhiqize ingcindezi yangaphakathi ngenxa yomehluko ekushintsheni kwevolumu ethile. Ngakho-ke, izinhlobo ezimbili zokucindezeleka kwangaphakathi zingase zenziwe ngesikhathi senqubo yokucisha nokupholisa: enye ingcindezi yokushisa; enye ingcindezi yezicubu.

Ngokuhambisana nezici zesikhathi sokuba khona zokucindezeleka kwangaphakathi, kungase futhi kuhlukaniswe kube ingcindezi esheshayo kanye nengcindezi eyinsalela. Ukucindezeleka kwangaphakathi okukhiqizwa i-workpiece ngesikhathi esithile phakathi nenqubo yokupholisa kubizwa ngokuthi ingcindezi esheshayo; ngemva kokuba i-workpiece selehlile, ingcindezi esele ngaphakathi kwendawo yokusebenza ibizwa ngokuthi i-residual stress.

Ukucindezeleka okushisayo kubhekisela ekucindezelekeni okubangelwa ukwanda okushisayo okungahambisani (noma ukufinyela okubandayo) ngenxa yokuhluka kwezinga lokushisa ezingxenyeni ezihlukene zocezu lokusebenza lapho kushisa (noma kupholiswa).

Manje thatha isilinda esiqinile njengesibonelo ukuze ubonise ukwakheka nokuguqula imithetho yokucindezeleka kwangaphakathi phakathi nenqubo yokupholisa. Ukucindezeleka kwe-axial kuphela okuxoxwa ngakho lapha. Ekuqaleni kokupholisa, ngoba ubuso buphola ngokushesha, izinga lokushisa liphansi, futhi liyancipha kakhulu, kuyilapho umgogodla upholile, izinga lokushisa liphezulu, futhi ukuncipha kuncane. Ngenxa yalokho, ingaphezulu kanye nengaphakathi kuvinjelwe ngokulinganayo, okuholela ekucindezelekeni okuqinile ebusweni, kuyilapho umnyombo ungaphansi kwengcindezi. ukucindezeleka. Njengoba ukupholisa kuqhubeka, umehluko wokushisa phakathi kwangaphakathi nangaphandle uyakhula, futhi ukucindezeleka kwangaphakathi nakho kuyanda ngokufanele. Lapho ukucindezeleka kwanda ukudlula amandla esivuno kulokhu kushisa, ukuguqulwa kwepulasitiki kwenzeka. Njengoba ubukhulu benhliziyo buphakeme kunobungaphezulu, inhliziyo ihlale ifinyela nge-axially kuqala. Ngenxa yokuguqulwa kwepulasitiki, ukucindezeleka kwangaphakathi akusakhuli. Ngemuva kokupholisa isikhathi esithile, ukwehla kwezinga lokushisa elingaphezulu kuzokwehla kancane kancane, futhi ukuncipha kwawo kuzokwehla kancane kancane. Ngalesi sikhathi, umnyombo usancipha, ngakho-ke ukucindezeleka okuqinile okungaphezulu kanye nokucindezeleka okucindezelayo kumgogodla kuzokwehla kancane kancane kuze kunyamalale. Kodwa-ke, njengoba ukupholisa kuqhubeka, umswakama ongaphezulu uyancipha futhi uphansi, futhi inani lokuncipha liya ngokuya lincipha, noma liyeke nokuncipha. Njengoba izinga lokushisa elingaphakathi lisephezulu, lizoqhubeka lincipha, futhi ekugcineni ukucindezeleka okucindezelayo kuzokwakhiwa ebusweni bomsebenzi wokusebenza, kuyilapho umgogodla uzoba nokucindezeleka okuqinile. Kodwa-ke, njengoba izinga lokushisa liphansi, ukuguqulwa kwepulasitiki akulula ukwenzeka, ngakho-ke lokhu kucindezeleka kuzokwanda njengoba ukupholisa kuqhubeka. Iyaqhubeka nokukhula futhi ekugcineni ihlala ngaphakathi kwe-workpiece njengengcindezi eyinsalela.

Kungabonakala ukuthi ukucindezeleka okushisayo phakathi nenqubo yokupholisa ekuqaleni kubangela ukuthi ungqimba olungaphezulu lunwetshwe futhi umgogodla ucindezelwe, futhi ukucindezeleka okusele okusele kuwungqimba olungaphezulu okumele lucindezelwe futhi umgogodla welulwe.

Ukufingqa, ingcindezi yokushisa ekhiqizwa phakathi nokupholisa kokucisha ibangelwa umehluko wezinga lokushisa eliwela phakathi kwenqubo yokupholisa. Uma izinga lokupholisa libe likhulu kanye nomehluko wezinga lokushisa elikhulu ezingxenyeni ezihlukene, kuba mkhulu ukucindezeleka okushisayo okukhiqizwayo. Ngaphansi kwezimo ezifanayo zokupholisa, ukuphakama kwezinga lokushisa kwendawo yokusebenza, usayizi omkhulu, ukuhanjiswa kwensimbi okushisayo kuncane, umehluko omkhulu wezinga lokushisa ngaphakathi kwendawo yokusebenza, kanye nokucindezeleka okukhulu kokushisa. Uma i-workpiece ipholile ngokungalingani ekushiseni okuphezulu, izohlanekezelwa futhi ikhubazeke. Uma ingcindezi esheshayo eqinile ekhiqizwa ngesikhathi sokupholisa isiqeshana somsebenzi inkulu kunamandla aqinile wento, kuzovela imifantu ecishayo.

Ukucindezeleka kokuguqulwa kwesigaba kubhekisela ekucindezelekeni okubangelwa isikhathi esihlukile sokuguqulwa kwesigaba ezingxenyeni ezihlukahlukene ze-workpiece phakathi nenqubo yokwelapha ukushisa, eyaziwa nangokuthi ukucindezeleka kwezicubu.

Ngesikhathi sokucisha kanye nokupholisa ngokushesha, lapho ungqimba olungaphezulu lupholile lufika endaweni ka-Ms, ukuguqulwa kwe-martensitic kwenzeka futhi kubangela ukwanda kwevolumu. Kodwa-ke, ngenxa yokuvinjwa komnyombo ongakenzi ukuguqulwa, ungqimba olungaphezulu lukhiqiza ukucindezeleka okucindezelayo, kuyilapho umgogodla unokucindezeleka okuqinile. Lapho ukucindezeleka kukhulu ngokwanele, kuzodala ukubola. Uma umgogodla upholiswe ku-Ms point, uzophinde wenze izinguquko ze-martensitic futhi ande ngevolumu. Kodwa-ke, ngenxa yemingcele yongqimba olungaphezulu oluguquliwe olune-plasticity ephansi namandla aphezulu, ukucindezeleka kwayo kokugcina okusele kuzoba ngendlela yokucindezeleka kwendawo, futhi okuyisisekelo kuyoba Ngaphansi kwengcindezi. Kungabonakala ukuthi ukuguqulwa kanye nesimo sokugcina sokucindezeleka kokuguqulwa kwesigaba kuphambene ncamashi nokucindezeleka okushisayo. Ngaphezu kwalokho, njengoba ukucindezeleka kokushintsha kwesigaba kwenzeka emazingeni okushisa aphansi ane-plasticity ephansi, ukuguqulwa kunzima ngalesi sikhathi, ngakho-ke ukucindezeleka kokushintsha kwesigaba kungenzeka kubangele ukuqhekeka kwe-workpiece.

Kunezici eziningi ezithinta ubukhulu bokucindezeleka kokuguqulwa kwesigaba. Ukusheshisa izinga lokupholisa lensimbi ebangeni lokushisa lokuguqulwa kwe-martensite, ubukhulu bocezu lwensimbi likhulu, ukuqhutshwa kokushisa kwensimbi kubi kakhulu, kukhudlwana umthamo othize we-martensite, kukhulu ukucindezeleka kokuguqulwa kwesigaba. Ikhula ibe nkulu. Ngaphezu kwalokho, ukucindezeleka kokuguqulwa kwesigaba kuhlobene nokubunjwa kwensimbi kanye nokuqina kwensimbi. Isibonelo, insimbi ephezulu ye-carbon high alloy yandisa umthamo othize we-martensite ngenxa yokuqukethwe kwayo kwekhabhoni ephezulu, okufanele ikhulise ukucindezeleka kokuguqulwa kwesigaba sensimbi. Kodwa-ke, njengoba okuqukethwe kwekhabhoni kukhuphuka, iphuzu lika-Ms liyancipha, futhi kunenani elikhulu le-austenite egciniwe ngemuva kokucisha. Ukunwetshwa kwevolumu yayo kuncipha futhi ingcindezi esele iphansi.

(2) Ukuguqulwa kwe-workpiece ngesikhathi sokucisha

Ngesikhathi sokucisha, kunezinhlobo ezimbili eziyinhloko zokuguqulwa ku-workpiece: enye inguquko yokuma kwejometri ye-workpiece, ebonakala njengezinguquko ngobukhulu nokuma, okuvame ukubizwa ngokuthi i-warping deformation, okubangelwa ukucindezeleka kokucindezeleka; enye i-volume deformation. , okubonakala njengokunwetshwa okulinganayo noma ukufinyezwa kwevolumu ye-workpiece, okubangelwa ukuguqulwa kwevolumu ethile ngesikhathi sokushintsha kwesigaba.

I-Warping deformation iphinde ihlanganise ukuguqulwa komumo kanye nokusonteka kwe-twisting. I-Twist deformation ibangelwa ikakhulukazi ukubekwa okungafanele kwe-workpiece esithandweni ngesikhathi sokushisa, noma ukuntuleka kokwelashwa kokubunjwa ngemva kokulungiswa kokuguqulwa ngaphambi kokucisha, noma ukupholisa okungalingani kwezingxenye ezihlukahlukene ze-workpiece lapho umsebenzi upholile. Lokhu kuguqulwa kungahlaziywa futhi kuxazululwe ezimweni ezithile. Okulandelayo kudingidwa ngokuyinhloko ukuguquguquka kwevolumu kanye nokuguqulwa komumo.

1) Izimbangela zokucisha i-deformation kanye nemithetho yayo eguqukayo

Ukuguqulwa kwevolumu okubangelwa ukuguqulwa kwesakhiwo Isimo sesakhiwo se-workpiece ngaphambi kokucisha ngokuvamile siyi-pearlite, okungukuthi, isakhiwo esixubile se-ferrite ne-cementite, futhi ngemva kokucisha isakhiwo se-martensitic. Amavolumu athile ahlukene alezi zicubu azodala ushintsho lwevolumu ngaphambi nangemva kokucisha, okuholela ekuguquguqukeni. Kodwa-ke, lokhu kuguqulwa kubangela kuphela ukuthi ucezu lokusebenza lwande futhi lunciphe ngokulinganayo, ngakho-ke akuguquli ukwakheka kwendawo yokusebenza.

Ngaphezu kwalokho, i-martensite eyengeziwe esakhiweni ngemva kokwelashwa kokushisa, noma ukuphakama kwekhabhoni ku-martensite, kuyanda ukunwetshwa kwevolumu yayo, kanye nenani elikhulu le-austenite egciniwe, ukunwetshwa kwevolumu encane. Ngakho-ke, ukuguqulwa kwevolumu kungalawulwa ngokulawula okuqukethwe okuhlobene kwe-martensite kanye ne-martensite esele ngesikhathi sokwelashwa kokushisa. Uma ilawulwa kahle, ivolumu ngeke ikhule noma inciphe.

Ukuguqulwa komumo okubangelwa ukucindezeleka okushisayo Ukuguqulwa okubangelwa ukucindezeleka okushisayo kwenzeka ezindaweni zokushisa eziphakeme lapho amandla okukhiqiza ezingxenye zensimbi ephansi, i-plasticity iphezulu, ubuso buphola ngokushesha, futhi umehluko wokushisa phakathi kwangaphakathi nangaphandle kwe-workpiece inkulu kakhulu. Ngalesi sikhathi, ingcindezi yokushisa esheshayo ingcindezi yokuqina komhlaba kanye nengcindezi ewumgogodla. Njengoba izinga lokushisa eliyisisekelo liphezulu ngalesi sikhathi, amandla okukhiqiza aphansi kakhulu kunobuso, ngakho-ke abonakala njenge-deformation ngaphansi kwesenzo sokucindezeleka kokucindezela okunezinhlangothi eziningi, okungukuthi, i-cube iyindilinga ekuqondeni. Izinhlobonhlobo. Umphumela uba ukuthi elikhulu liyashwabana, kuyilapho elincane liyakhula. Isibonelo, isilinda eside sifinyela ekuqondeni kobude futhi sinwebeke endaweni yobubanzi.

Ukuguquguquka komumo okubangelwa ukucindezeleka kwezicubu Ukuguquguquka okubangelwa ukucindezeleka kwezicubu nakho kwenzeka ngesikhathi sokuqala lapho ukucindezeleka kwezicubu kuphezulu. Ngalesi sikhathi, umehluko wokushisa we-cross-section mkhulu, izinga lokushisa eliyisisekelo liphakeme, lisesimweni se-austenite, i-plasticity yinhle, futhi amandla okukhiqiza aphansi. Ukucindezeleka kwezicubu ezisheshayo ukucindezelwa kwe-surface compressive kanye ne-core tensile stress. Ngakho-ke, i-deformation ibonakala njengokwelulwa komongo ngaphansi kwesenzo sokucindezeleka okuneziqondiso eziningi. Umphumela uba ukuthi ngaphansi kwesenzo sokucindezeleka kwezicubu, uhlangothi olukhudlwana lwe-workpiece lunwebeka, kuyilapho oluncane lufinyeza. Isibonelo, ukuguquguquka okubangelwa ukucindezeleka kwezicubu kusilinda ende ubude nokuncipha kobubanzi.

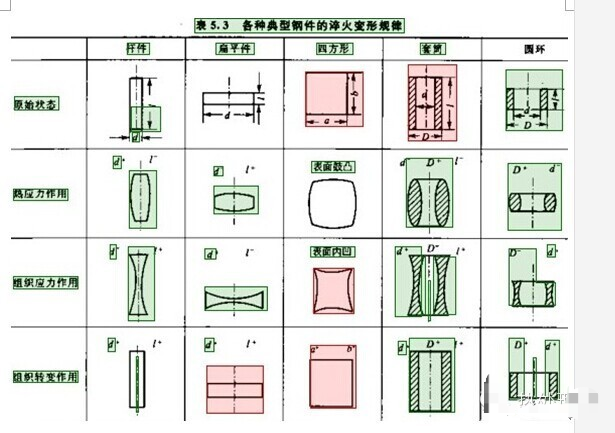

Ithebula 5.3 libonisa imithetho yokucisha yokuguqula izingxenye ezihlukahlukene zensimbi ezivamile.

I-2) Izinto ezithinta ukuguqulwa kokucima

Izici ezithinta ukuguqulwa kokucisha ngokuyinhloko ukwakheka kwamakhemikhali ensimbi, isakhiwo sokuqala, i-geometry yezingxenye kanye nenqubo yokwelapha ukushisa.

3) Ukucisha imifantu

Imifantu ezingxenyeni ikakhulukazi kwenzeka ekupheleni kwesigaba sokucisha nokupholisa, okungukuthi, ngemva kokuba ukuguqulwa kwe-martensitic kuqediwe ngokuyisisekelo noma ngemva kokupholisa okuphelele, ukwehluleka okuphukayo kwenzeka ngenxa yokuthi ukucindezeleka okuqinile ezingxenyeni kudlula amandla okuphuka kwensimbi. Imifantu ivamise ukuba yi-perpendicular to the direction of maximum tensile deformation, ngakho-ke izinhlobo ezahlukene zokuqhekeka ezingxenyeni zincike kakhulu esimweni sokusabalalisa ingcindezi.

Izinhlobo ezivamile zokuqhekeka kokucisha: Imifantu ye-Longitudinal (axial) ikhiqizwa ikakhulukazi lapho ukucindezeleka kwe-tangential tensile kudlula amandla okuphuka kwezinto; imifantu ephambanayo kwakheka lapho ukucindezelwa okukhulu kwe-axial okwakhiwa endaweni engaphakathi yengxenye kudlula amandla okuphuka kwento. Imifantu; ukuqhekeka kwenethiwekhi kwakhiwa ngaphansi kwesenzo sokucindezeleka kwe-two-dimensional tensile ebusweni; ukuxebuka kwemifantu kwenzeka ongqimbeni oluqinile oluncane kakhulu, olungase lwenzeke lapho ukucindezeleka kushintsha kakhulu futhi ukucindezeleka okuqinile okweqile kungena ohlangothini lwe-radial. Uhlobo lokuqhekeka.

Ukuqhekeka kwe-longitudinal kubizwa nangokuthi imifantu ye-axial. Imifantu kwenzeka lapho kucindezelwa okukhulu kakhulu eduze nendawo, futhi ibe nokujula okuthile maphakathi. Isiqondiso semifantu ngokuvamile sihambisana ne-eksisi, kodwa isiqondiso singase futhi sishintshe lapho kukhona ukugxila kwengcindezi engxenyeni noma uma kukhona ukukhubazeka kwangaphakathi kwesakhiwo.

Ngemuva kokuthi i-workpiece isicime ngokuphelele, imifantu ye-longitudinal ijwayele ukwenzeka. Lokhu kuhlobene nengcindezi enkulu ye-tangential tensile ebusweni bomsebenzi ocishiwe. Njengoba okuqukethwe kwekhabhoni yensimbi kwanda, ukuthambekela kokwenza imifantu ye-longitudinal kuyanda. Insimbi ye-carbon ephansi inomthamo omncane othize we-martensite kanye nokucindezeleka okushisayo okuqinile. Kukhona ingcindezi enkulu eyinsalela ecindezelayo ngaphezulu, ngakho akulula ukucinywa. Njengoba okuqukethwe kwekhabhoni kwanda, ingcindezi yokucindezela phezulu iyancipha futhi ukucindezeleka kwesakhiwo kuyanda. Ngasikhathi sinye, umfutho we-peak tensile udlulela kungqimba olungaphezulu. Ngakho-ke, i-carbon steel ephezulu ijwayele ukuqhekeka kokucisha i-longitudinal lapho ishisa ngokweqile.

Ubukhulu bezingxenye buthinta ngokuqondile usayizi nokusatshalaliswa kokucindezeleka okusele, futhi ukuthambekela kwayo kokucisha ukuqhekeka nakho kuhlukile. Imifantu ye-longitudinal nayo yakheka kalula ngokucisha phakathi kwebanga losayizi wesigaba esiphambanayo esiyingozi. Ngaphezu kwalokho, ukuvinjwa kwensimbi yezinto zokusetshenziswa kuvame ukubangela ukuqhekeka kwe-longitudinal. Njengoba izingxenye eziningi zensimbi zenziwa ngokugoqa, okufakiwe okungeyona igolide, ama-carbides, njll. ensimbi kusakazwa ngokuhambisana nesiqondiso se-deformation, okwenza insimbi ibe yi-anisotropic. Isibonelo, uma insimbi yethuluzi inesakhiwo esifana nebhande, amandla ayo okuphuka avundlayo ngemva kokucisha mancane ngo-30% kuya ku-50% kunamandla okuphuka kwe-longitudinal. Uma kunezici ezifana ne-non-gold inclusions ensimbi ebangela ukugxila kokucindezeleka, ngisho noma ukucindezeleka kwe-tangential kukhulu kunokucindezeleka kwe-axial, ukuqhekeka kwe-Longitudinal kulula ukwenza ngaphansi kwezimo eziphansi zokucindezeleka. Ngenxa yalesi sizathu, ukulawulwa okuqinile kwezinga lokungenayo i-metallic inclusions kanye noshukela ensimbi kuyisici esibalulekile ekuvimbeleni imifantu yokucisha.

Izici zokusabalalisa ukucindezeleka kwangaphakathi zokuqhekeka okuphambene nokuqhekeka kwe-arc yilezi: indawo engaphezulu ingaphansi kwengcindezi ecindezelayo. Ngemva kokushiya indawo ebangeni elithile, ukucindezeleka okucindezelayo kushintsha ekucindezelekeni okukhulu okuqinile. Ukuqhekeka kwenzeka endaweni yokucindezeleka okuqinile, bese kuthi lapho ukucindezeleka kwangaphakathi Kusakazeka ebusweni bengxenye kuphela uma isatshalaliswa kabusha noma i-brittleness yensimbi iyanda.

Ukuqhekeka okuguquguqukayo kuvame ukwenzeka ezingxenyeni ezinkulu ze-shaft, njengama-roller, ama-turbine rotor noma ezinye izingxenye ze-shaft. Izici zokuqhekeka ziwukuthi zihambisana nesiqondiso se-axis futhi ziphuka kusukela ngaphakathi kuya ngaphandle. Zivame ukubunjwa ngaphambi kokuqina futhi zibangelwa ukucindezeleka okushisayo. Ama-forging amakhulu avame ukuba nokukhubazeka kwe-metallurgical njengama-pores, inclusions, imifantu yokubumba kanye namachashaza amhlophe. Lezi zinkinga zisebenza njengendawo yokuqala yokuphuka nokuphuka ngaphansi kwesenzo se-axial tensile stress. Ukuqhekeka kwe-arc kubangelwa ukucindezeleka okushisayo futhi kuvame ukusabalalisa ngesimo se-arc ezingxenyeni lapho ukwakheka kwengxenye kushintsha khona. Ivela kakhulu ngaphakathi kwendawo yokusebenza noma eduze nemiphetho ebukhali, ama-grooves nezimbobo, futhi isatshalaliswa ngendlela ye-arc. Uma izingxenye zensimbi ezinekhabhoni ephezulu ezinobubanzi noma ukujiya okungama-80 kuya ku-100 mm noma ngaphezulu zingacinywa, indawo engaphezulu izobonisa ingcindezi ecindezelayo futhi isikhungo sizobonisa ingcindezi eqinile. Ingcindezi, ukucindezelwa okukhulu kwengcindezi kwenzeka endaweni yoguquko ukusuka kungqimba oluqinile ukuya kwengaqinile, futhi ukuqhekeka kwe-arc kwenzeka kulezi zindawo. Ngaphezu kwalokho, izinga lokupholisa emaphethelweni abukhali nasemakhoneni liyashesha futhi zonke ziyacinywa. Lapho ushintshela ezingxenyeni ezithambile, okungukuthi, endaweni engaqinile, indawo yokucindezeleka ephezulu kakhulu ibonakala lapha, ngakho-ke imifantu ye-arc ijwayele ukwenzeka. Izinga lokupholisa eduze kwembobo yephini, igroove noma imbobo emaphakathi yocezu lokusebenza lihamba kancane, ungqimba oluqinile oluhambisanayo luncane, futhi ukucindezeleka okuqinile eduze kwendawo yoguquko eqinile kungabangela kalula imifantu ye-arc.

Imifantu ye-reticular, eyaziwa nangokuthi imifantu engaphezulu, iyimifantu engaphezulu. Ukujula kokuqhekeka akujulile, ngokuvamile cishe ku-0.01 ~ 1.5mm. Isici esiyinhloko salolu hlobo lokuqhekeka ukuthi isiqondiso esinqunyiwe sokuqhekeka akuhlangene nokuma kwengxenye. Imifantu eminingi ixhunywe komunye nomunye ukwenza inethiwekhi futhi isakazwa kabanzi. Uma ukujula kokuqhekeka kukukhudlwana, okungaphezu kuka-1 mm, izici zenethiwekhi ziyanyamalala futhi zibe imifantu eqondiswa ngokungahleliwe noma esabalaliswe ngobude. Ukuqhekeka kwenethiwekhi kuhlobene nesimo sokucindezelwa kwe-two-dimensional tensile endaweni.

Ikhabhoni ephezulu noma izingxenye zensimbi ezenziwe nge-carburized ezinesendlalelo se-decarburized ngaphezulu zijwayele ukwenza imifantu yenethiwekhi ngesikhathi sokucisha. Lokhu kungenxa yokuthi ungqimba olungaphezulu lunokuqukethwe kwekhabhoni ephansi kanye nevolumu ethile encane kunongqimba lwangaphakathi lwe-martensite. Ngesikhathi sokucisha, ungqimba olungaphezulu lwe-carbide lungaphansi kwengcindezi eqinile. Izingxenye ungqimba lwazo lwe-dephosphorization lungakasuswa ngokuphelele phakathi nokucubungula ngomshini zizophinda zenze imifantu yenethiwekhi phakathi ne-high-frequency noma ukucisha indawo yomlilo. Ukuze ugweme imifantu enjalo, izinga eliphezulu lezingxenye kufanele lilawulwe ngokuqinile, futhi ukushiswa kwe-oxidation kufanele kuvinjelwe ngesikhathi sokwelashwa kokushisa. Ngaphezu kwalokho, ngemva kokuba ukufa kokubumba kusetshenziswe isikhathi esithile, ukuqhekeka kokukhathala okushisayo okuvela emicu noma amanethiwekhi emgodini kanye nemifantu yenqubo yokugaya yezingxenye ezicishiwe konke kungokwaleli fomu.

Imifantu ecwecwayo yenzeka endaweni encane kakhulu yongqimba olungaphezulu. Ingcindezi ecindezelayo isebenza kuma-axial kanye nezikhombisi-ndlela ze-tangential, futhi ukucindezeleka okuqinile kwenzeka ohlangothini lwe-radial. Imifantu ihambisana nobuso bengxenye. Ukuxebuka kongqimba oluqinile ngemva kokucisha indawo engaphezulu kanye nezingxenye zokungcwatshwa kwe-carburizing zipholile kungokwaleyo mifantu. Ukuvela kwayo kuhlobene nesakhiwo esingalingani kungqimba oluqinile. Isibonelo, ngemuva kokuba i-alloy carburized steel ipholiswe ngesivinini esithile, isakhiwo esisengqimbeni se-carburized sithi: ungqimba lwangaphandle lwe-pearlite + carbide enhle kakhulu, futhi i-sublayer iyi-martensite + residual Austenite, ungqimba lwangaphakathi luyi-pearlite enhle noma isakhiwo esihle kakhulu se-pearlite. Njengoba ukwakheka kwevolumu ethile ye-sub-layer martensite inkulu kakhulu, umphumela wokunwetshwa kwevolumu ukuthi ukucindezeleka okucindezelayo kusebenza phezu kongqimba olungaphezulu ku-axial kanye nezikhombisi-ndlela ze-tangential, futhi ukucindezeleka okuqinile kwenzeka endaweni ye-radial, futhi ukuguqulwa kwengcindezi kwenzeka ngaphakathi, ukushintshela esimweni sokucindezeleka esicindezelayo, kanye nokuqhekeka kokuxebuka Kwenzeka ezindaweni ezincane kakhulu lapho ukuguqulwa kokucindezeleka kucijile. Ngokuvamile, imifantu ilala ngaphakathi ngokuhambisana phezulu, futhi ezimweni ezimbi kakhulu ingase ibangele ukuxebuka. Uma izinga lokupholisa lezingxenye ze-carburized liyasheshisa noma lincishisiwe, isakhiwo se-martensite se-uniform noma isakhiwo se-pearlite se-ultra-fine singatholakala kungqimba lwe-carburized, olungavimbela ukuvela kwemifantu enjalo. Ukwengeza, ngesikhathi sokucisha kwe-high-frequency noma i-flame surface, indawo engaphezulu ivame ukushisa ngokweqile futhi i-inhomogeneity yesakhiwo eduze nongqimba oluqinile lungakha kalula imifantu enjalo.

Ama-Microcracks ahlukile kule mifantu emine eshiwo ngenhla ngoba abangelwa i-microstress. Ukuqhekeka kwe-Intergranular okuvela ngemva kokucisha, ukushisa ngokweqile nokugaya kwensimbi yensimbi enekhabhoni ephezulu noma izinto zokusebenza ezenziwe nge-carburized, kanye nokuqhekeka okubangelwa ukungashisa ngesikhathi kwezingxenye ezicishiwe, konke kuhlobene nokuba khona kanye nokwandiswa kwama-microcracks ensimbi.

Ama-Microcracks kufanele ahlolwe ngaphansi kwesibonakhulu. Ngokuvamile zenzeka emingceleni yokuqala yezinhlamvu ze-austenite noma lapho kuhlangana khona amashidi e-martensite. Eminye imifantu ingena emashidini e-martensite. Ucwaningo lubonisa ukuthi ama-microcracks avame kakhulu ku-martensite e-twinned flaky. Isizathu siwukuthi i-martensite ene-flaky ishayisana lapho ikhula ngesivinini esikhulu futhi idala ukucindezeleka okukhulu. Kodwa-ke, i-martensite enamawele ngokwayo i-brittle futhi ayikwazi ukukhiqiza i-Plastic deformation ikhulula ukucindezeleka, ngaleyo ndlela ibangele kalula ama-microcracks. Izinhlamvu ze-austenite ziqinile futhi ukuthambekela kwe-microcracks kuyanda. Ukuba khona kwama-microcracks ensimbi kuzonciphisa kakhulu amandla kanye ne-plasticity yezingxenye ezicishiwe, okuholela ekulimaleni kwangaphambili (ukuphuka) kwezingxenye.

Ukuze ugweme ama-microcracks ezingxenyeni zensimbi ezinekhabhoni ephezulu, izinyathelo ezifana nezinga lokushisa eliphansi lokucisha, ukuthola isakhiwo esihle se-martensite, nokunciphisa okuqukethwe kwekhabhoni ku-martensite kungathathwa. Ngaphezu kwalokho, ukuthukuthela okufika ngesikhathi ngemva kokucisha kuyindlela ephumelelayo yokunciphisa ukucindezeleka kwangaphakathi. Ukuhlolwa kuye kwafakazela ukuthi ngemva kokushisa okwanele okungaphezu kuka-200 ° C, ama-carbides atholakala emifantwini anomphumela "wokushisela" imifantu, enganciphisa kakhulu izingozi ze-microcracks.

Okungenhla yingxoxo yezimbangela nezindlela zokuvimbela imifantu ngokusekelwe kuphethini yokusabalalisa imifantu. Ekukhiqizeni kwangempela, ukusatshalaliswa kwemifantu kuyahlukahluka ngenxa yezici ezifana nekhwalithi yensimbi, ukuma kwengxenye, nobuchwepheshe bokucubungula okushisayo nokubanda. Ngezinye izikhathi imifantu isivele ikhona ngaphambi kokwelashwa kokushisa futhi iqhubeke yanda phakathi nenqubo yokucisha; ngezinye izikhathi izinhlobo eziningana zokuqhekeka zingavela engxenyeni efanayo ngesikhathi esisodwa. Kulokhu, ngokusekelwe ezicini ze-morphological of the crack, ukuhlaziywa kwe-macroscopic ye-fracture surface, ukuhlolwa kwe-metallographic, futhi uma kunesidingo, ukuhlaziywa kwamakhemikhali nezinye izindlela kufanele kusetshenziselwe ukwenza ukuhlaziya okuphelele kusuka kukhwalithi yezinto ezibonakalayo, isakhiwo senhlangano kuya ezimbangela zokucindezeleka kokwelashwa kokushisa ukuze kutholakale ukuqhuma. izimbangela eziyinhloko bese unquma izinyathelo zokuvimbela eziphumelelayo.

Ukuhlaziywa kokuqhekeka kwemifantu kuyindlela ebalulekile yokuhlaziya izimbangela zokuqhekeka. Noma yikuphi ukuphuka kunendawo yokuqala yokuqhekeka. Imifantu ecisha ngokuvamile iqala ukusuka endaweni yokuhlangana yokuqhekeka kwama-radial.

Uma umsuka woqhekeko ukhona ebusweni bengxenye, kusho ukuthi ukuqhekeka kubangelwa ukucindezeleka ngokweqile okunamandla ebusweni. Uma kungekho ukukhubazeka kwesakhiwo njengokufakwa phezulu, kodwa kunezici zokugxilisa ingcindezi ezifana nezimpawu zommese ezinzima, isikali se-oxide, amakhona acijile ezingxenye zensimbi, noma izingxenye zokuguqulwa kwesakhiwo, kungenzeka ukuqhekeka.

Uma imvelaphi yokuqhekeka ingaphakathi kwengxenye, ihlobene nokukhubazeka kwempahla noma ukucindezeleka okusalelayo okusalela ngokweqile kwangaphakathi. Indawo ephukile yokucisha okuvamile impunga kanye ne-porcelain ecolekile. Uma indawo ephukile impunga emnyama futhi ilukhuni, kubangelwa ukushisa ngokweqile noma izicubu zokuqala ziwugqinsi.

Ngokuvamile, akumele kube nombala we-oxidation engxenyeni yengilazi yokuqhekeka okucishayo, futhi akumele kube khona ukukhishwa kwe-carburization eduze nokuqhekeka. Uma kukhona i-decarburization ezungeze ukuqhuma noma umbala oxidized engxenyeni yokuqhekeka, kubonisa ukuthi ingxenye isivele inemifantu ngaphambi kokucisha, futhi imifantu yasekuqaleni izokhula ngaphansi kwethonya lokucindezeleka kokwelashwa kokushisa. Uma i-carbides ehlukanisiwe kanye ne-inclusions ibonakala eduze nokuqhekeka kwengxenye, kusho ukuthi ukuqhekeka kuhlobene nokuhlukaniswa okunzima kwe-carbides ezintweni eziluhlaza noma ukuba khona kokufakwayo. Uma imifantu ibonakala kuphela emakhoneni acijile noma imise izingxenye zokuguqulwa kwengxenye ngaphandle kwento engenhla, kusho ukuthi ukuqhekeka kubangelwa ukuklanywa kwesakhiwo okungenangqondo kwengxenye noma izinyathelo ezingalungile zokuvimbela imifantu, noma ukucindezeleka ngokweqile kokwelashwa kokushisa.

Ngaphezu kwalokho, imifantu ekwelapheni ukushisa kwamakhemikhali kanye nezingxenye zokucisha indawo ngokuvamile zivela eduze kongqimba oluqinile. Ukuthuthukisa isakhiwo sesendlalelo esiqinile nokunciphisa ukucindezeleka kokwelashwa kokushisa kuyizindlela ezibalulekile zokugwema imifantu ebusweni.

Isikhathi sokuthumela: May-22-2024