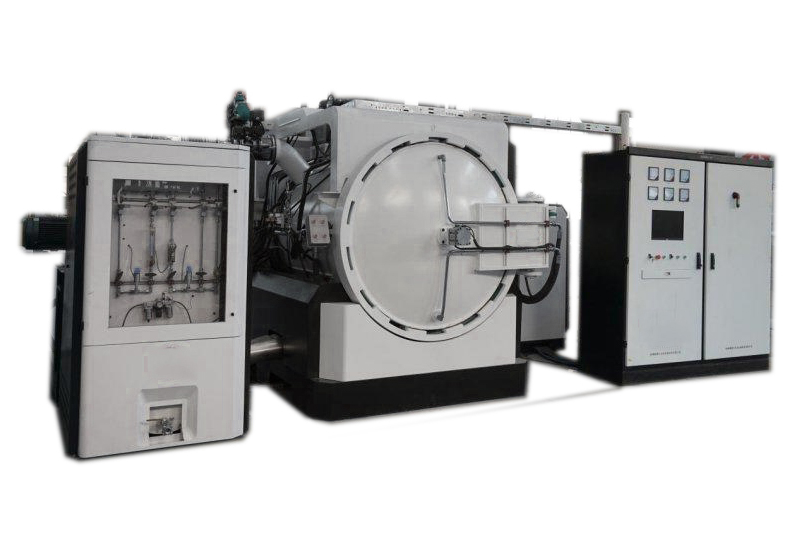

Isithando somlilo se-vacuum sintering sisetshenziselwa kakhulu inqubo yokucwilisa izingxenye ze-semiconductor kanye namadivayisi okulungisa amandla.Ingakwazi ukwenza i-vacuum sintering, i-sintering evikelwe ngegesi kanye ne-sintering evamile.Kuyimishini yenqubo yenoveli ochungechungeni lwemishini ye-semiconductor ekhethekile.Inomqondo wokuklama inoveli, ukusebenza okulula kanye nesakhiwo esihlangene.Ukugeleza kwezinqubo eziningi kungaqedwa kumshini owodwa.Ingasetshenziswa futhi ekwelapheni ukushisa kwe-vacuum, i-vacuum brazing nezinye izinqubo kwezinye izinkambu.

Amakhono adingekayo okusetshenziswa kwesithando somlilo we-vacuum sintering

Isithando somlilo esiphezulu se-vacuum sintering sisetshenziselwa ukwenza i-tungsten crucible kukhoyili ikhiqize izinga lokushisa eliphezulu ngaphansi kokuvikelwa kokugcwaliswa kwe-hydrogen ngemva kokupompa i-vacuum kanye nesimiso sokushisa okuphakathi kwe-frequency induction, edluliselwa emsebenzini ngokusebenzisa imisebe eshisayo.Ilungele ukwenziwa kwempushana kanye nokucwiliswa kwama-alloys aphikisayo njenge-tungsten, i-molybdenum kanye nama-alloys awo ocwaningweni lwesayensi namayunithi ezimboni zempi.Indawo lapho isithando somlilo sifakwe khona izohlangabezana nezidingo zokuhlanzeka kwe-vacuum, umoya ozungezile uyobe uhlanzekile futhi womile, futhi kuzoba nezimo ezinhle zokungenisa umoya.Indawo yokusebenza akulula ukuphakamisa uthuli, njll.

Amakhono okusebenzisa nsuku zonke wesithando somlilo se-vacuum sintering:

1. Hlola ukuthi zonke izingxenye nezinsiza kukhabhinethi yokulawula ziphelele futhi ziqinile.

2. Ikhabhinethi yokulawula izofakwa esisekelweni esihambisanayo futhi ilungiswe.

3. Ngokomdwebo wezintambo futhi ubhekisela kumdwebo wohlelo lukagesi, xhuma umjikelezo oyinhloko wangaphandle kanye nesifunda sokulawula, futhi usekelwe ngokuthembekile ukuze uqinisekise izintambo ezifanele.

4. Hlola ukuthi ingxenye enyakazayo kagesi kufanele ihambe ngokukhululeka ngaphandle kokuminyana.

5. Ukumelana ne-insulation akufanele kube ngaphansi kwe-2 megohm.

6. Wonke ama-valve esithandweni sikagesi sevacuum kufanele abe sendaweni evaliwe.

7. Beka iswishi yamandla okulawula endaweni yokucisha.

8. Phendula iknobhu yokulawula ukucindezela ngokuphambene newashi.

9. Faka inkinobho ye-alamu endaweni evulekile.

10. Qedela ukuxhuma kwamanzi okupholisa azungezayo emishini ngokohlelo.Kutuswa ukuthi umsebenzisi axhume amanye amanzi abekwe eceleni (amanzi kampompi atholakalayo) epayipini elingenisayo nelikhiphayo lamathuluzi ukuvimbela iringi yokuvala ukuthi ingashi ngenxa yokwehluleka ukujikeleza kwamanzi noma ukuphelelwa amandla.

Isikhathi sokuthumela: May-07-2022