igesi yokucima umlilo yokucima umlilo Ivundlile enekamelo elilodwa

Yini i-vacuum gas quenching

I-vacuum gas quenching iyinqubo yokushisisa i-workpiece ngaphansi kwe-vacuum, bese uyipholisa ngokushesha kwigesi yokupholisa ngomfutho ophezulu kanye nezinga lokugeleza okuphezulu, ukuze kuthuthukiswe ubulukhuni obungaphezulu bomsebenzi wokusebenza.

Uma kuqhathaniswa nokucisha igesi okujwayelekile, ukucisha uwoyela kanye nokucisha okugeza usawoti, ukucisha igesi enomfutho ophezulu we-vacuum kunezinzuzo ezisobala: ikhwalithi ephezulu, akukho oxidation futhi akukho carburization; ukufana okuhle kokucisha kanye ne-deformation encane ye-workpiece; Ukulawulwa okuhle kwamandla okucisha kanye nezinga lokupholisa elilawulekayo; Ukukhiqiza okuphezulu, ukonga umsebenzi wokuhlanza ngemuva kokucisha; Akukho ukungcoliswa kwemvelo.

Kunezinto eziningi ezilungele ukucisha igesi yokucindezela okuphezulu, ikakhulukazi okuhlanganisa: insimbi enesivinini esikhulu (njengamathuluzi okusika, isikhunta sensimbi, ama-dies, amageji, ama-bearings ezinjini ze-jet), insimbi yamathuluzi (izingxenye zewashi, izinto ezilungiswayo, umshini wokunyathelisa), insimbi yokufa, insimbi ethwalayo, njll.

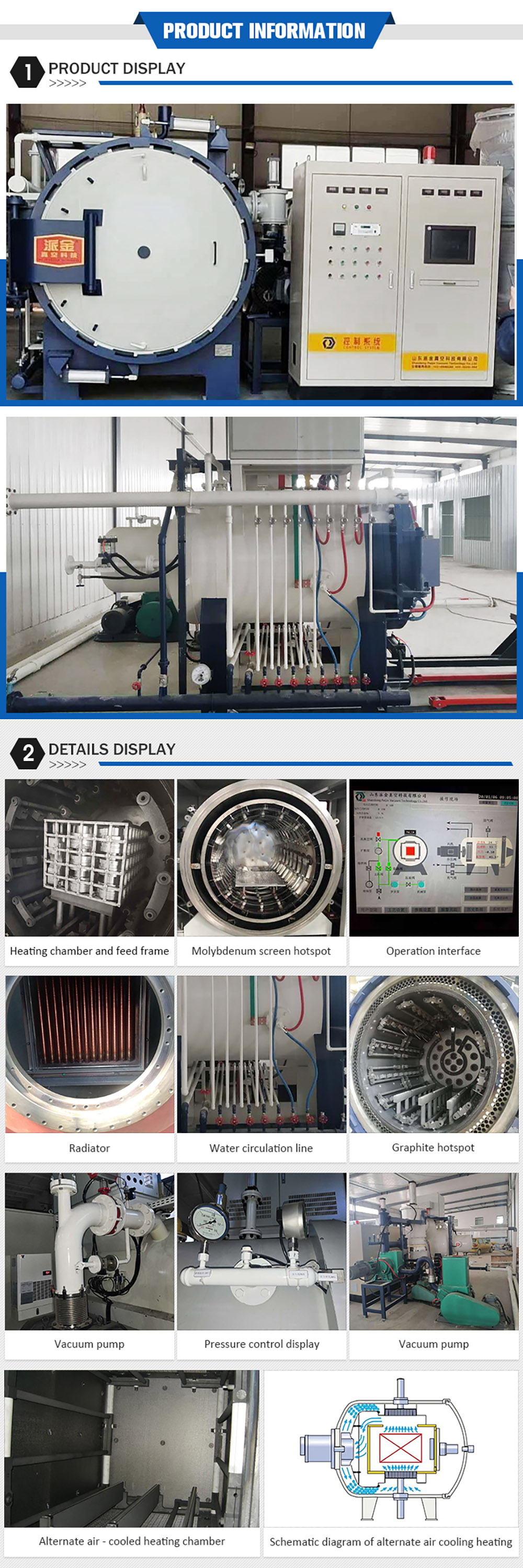

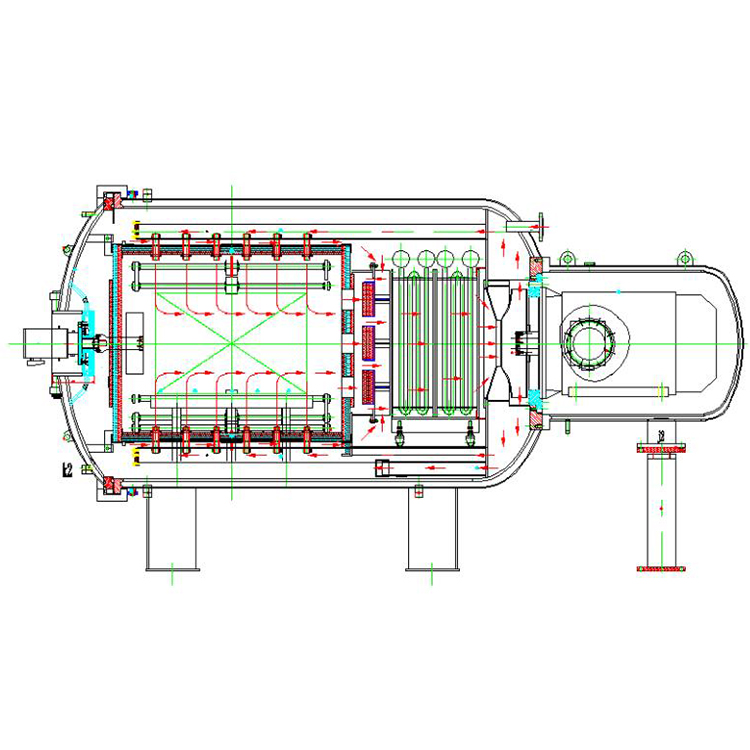

I-Paijin Vacuum gas quenching furnace iyisithando somlilo esihlanganisa umzimba wesithando somlilo, igumbi lokufudumala, i-hot mixing fan, uhlelo lwe-vacuum, uhlelo lokugcwalisa igesi, uhlelo lwe-vacuum partial pressure system, uhlelo lokulawula ugesi, uhlelo lokupholisa amanzi, uhlelo lokucisha igesi, uhlelo lwe-pneumatic, isistimu yokuphakela amandla okuzenzakalelayo kanye nesithando somlilo esizenzakalelayo.

Isicelo

I-Paijin Vacuum igesi yokucisha isithando somliloilungele ukucisha ukwelashwa kwezinto ezifana nensimbi yokufa, insimbi enesivinini esikhulu, insimbi engagqwali, njll; ukwelashwa kwesixazululo sezinto ezifana nensimbi engagqwali, i-titanium ne-titanium alloy; ukwelashwa kwe-annealing kanye nokwelashwa kwe-teering yezinto ezihlukahlukene kazibuthe; futhi ingasetshenziselwa i-vacuum brazing kanye ne-vacuum sintering.

Izici

1. Isivinini sokupholisa esiphezulu:ngokusebenzisa isishintshi sokushisa esiyisikwele esisebenza kahle kakhulu, izinga lokupholisa kwalo lenyuka ngo-80%.

2. Ukufana okuhle kokupholisa:Imibhobho yomoya ilingana futhi iyadiyazela isethwe nxazonke zegumbi lokufudumeza.

3.Ukonga Amandla Okuphezulu:Ama-nozzles ayo omoya azovala ngokuzenzakalelayo ekushisiseni, okwenza amandla ayo abize kancane ngo-40%.

4. Ukufana kwezinga lokushisa okungcono:izakhi zayo zokushisa zibekwe ngokulinganayo nxazonke zegumbi lokushisa.

5. Ifanele izindawo ezihlukene zenqubo:Isendlalelo se-insulation segumbi layo lokufudumeza senziwa ngongqimba oluhlanganisiwe oluqinile lokuvikela noma isikrini sokuvikela insimbi, esilungele izindawo ezihlukahlukene.

6. Ihlakaniphile futhi kulula ukucubungula uhlelo, isenzo esizinzile nesithembekile, ngokuzenzakalelayo, ngokuzenzakalelayo noma ngokusabisa ngesandla nokubonisa amaphutha.

7. Ukulawula ukuguqulwa kwemvamisa yokulawula igesi yokucisha ifeni, ukushisa komoya oshintshwayo ongakukhetha, inhlolovo yezinga lokushisa engamaphoyinti angu-9, ukucima ukucindezela ingxenye kanye nokucisha i-isothermal.

8. Ngalo lonke uhlelo lokulawula lwe-AI kanye nohlelo lokusebenza olwengeziwe lwemanuwali.

Ukucaciswa kwemodeli ejwayelekile kanye nemingcele

| Ukucaciswa kwemodeli ejwayelekile kanye nemingcele | |||||

| Imodeli | I-PJ-Q557 | I-PJ-Q669 | I-PJ-Q7711 | I-PJ-Q8812 | I-PJ-Q9916 |

| Indawo Eshisayo Esebenzayo LWH (mm) | 500*500*700 | 600*600*900 | 700*700 * 1100 | 800*800 * 1200 | 900*900 * 1600 |

| Isisindo Somthwalo(kg) | 300 | 500 | 800 | 1200 | 2000 |

| Izinga lokushisa eliphezulu(℃) | 1350 | ||||

| Ukunemba kokulawula izinga lokushisa(℃) | ±1 | ||||

| Ukufana kwezinga lokushisa kwesithando somlilo(℃) | ±5 | ||||

| I-Maximum Vacuum Degree(Pa) | 4.0 * E -1 | ||||

| Izinga lokunyusa ingcindezi (Pa/H) | ≤ 0.5 | ||||

| Ukucindezela kokucisha igesi (Ibha) | 10 | ||||

| Ukwakhiwa kwesithando somlilo | Igumbi elivundlile, elilodwa | ||||

| Indlela yokuvula umnyango wesithando somlilo | Uhlobo lwehinge | ||||

| Izakhi zokushisa | Izakhi zokushisa ze-Graphit | ||||

| Igumbi lokushisisa | Isakhiwo se-Graphit esizwakala kanzima nesithambile | ||||

| Uhlobo lokugeleza kokucisha igesi | Ukugeleza okushintshanayo okuqondile | ||||

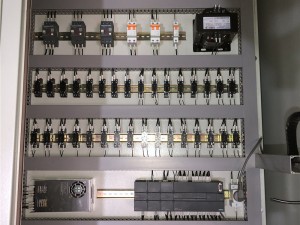

| I-PLC nezinto zikagesi | Siemens | ||||

| Isilawuli sezinga lokushisa | EUROTHERM | ||||

| Iphampu ye-vacuum | Iphampu yemishini kanye nepompo yezimpande | ||||

| Ububanzi ongazikhethela obungokwezifiso | |||||

| Izinga lokushisa eliphezulu | 600-2800 ℃ | ||||

| Izinga lokushisa eliphezulu | 6.7 * E -3 Pa | ||||

| Ukucindezela kokucisha igesi | 6-20 Ibha | ||||

| Ukwakhiwa kwesithando somlilo | Evundlile, Eqondile, Igumbi elilodwa noma amakamelo amaningi | ||||

| Indlela yokuvula umnyango | Uhlobo lwehinge, uhlobo lokuphakamisa, uhlobo oluyisicaba | ||||

| Izakhi zokushisa | Izinto zokushisisa ze-Graphit, izinto zokushisisa ze-Mo | ||||

| Igumbi lokushisisa | I-Graphite Ehlanganisiwe izwakele, Sonke isikrini esibonisa insimbi | ||||

| Uhlobo lokugeleza kokucisha igesi | Ukugeleza kwegesi eshintshanayo evundlile;Ukugeleza kwegesi eshintshanayo eqondile | ||||

| Vacuum amaphampu | Ipompo yemishini kanye nepompo yezimpande; Amaphampu omshini, izimpande kanye nokusabalalisa | ||||

| I-PLC nezinto zikagesi | Siemens;Omron;Mitsubishi;Siemens | ||||

| Isilawuli sezinga lokushisa | EUROTHERM;SHIMADEN | ||||

Ikhwalithi yokulawula

Ikhwalithi ingumoya wemikhiqizo, iphuzu eliyinhloko linquma imboni'Ikusasa.I-Paijin ithatha ikhwalithi njengezindaba eziza kuqala emsebenzini wethu wansuku zonke.Ukuqinisekisa ikhwalithi enhle yemikhiqizo yethu, sinake kakhulu izici ezi-3.

1.Okubaluleke kakhulu: Umuntu. Umuntu uyiphuzu elibaluleke kakhulu kuwo wonke umsebenzi. Sinezifundo eziphelele zokuqeqesha zaso sonke isisebenzi esisha, futhi sinesistimu yokulinganisa yokukala isisebenzi ngasinye ezingeni (abancane, abaphakathi, abaphezulu), abasebenzi bamazinga ahlukene baqashelwa imisebenzi ehlukene ngamaholo ahlukene. Kulolu hlelo lokulinganisa, it's hhayi amakhono kuphela, kodwa futhi isilinganiso umthwalo kanye namaphutha izinga, amandla okuphatha njll. Ngale ndlela, abasebenzi efektri yethu bazimisele ukwenza okungcono kakhulu emsebenzini wakhe.Futhi ukulandela ngokuqinile imithetho yokuphatha izinga.

2. Izinto ezisetshenziswayo nezingxenye ezingcono kakhulu: Sithenga kuphela izinto ezihamba phambili emakethe, siyazi ukuthi ukonga idola elingu-1 ezintweni ezibonakalayo kungabiza amadola ayi-1000 ekugcineni. Izingxenye ezibalulekile ezifana nezingxenye zikagesi namaphampu ziyimikhiqizo yomkhiqizo efana ne-Siemens, i-Omron, i-Eurotherm, i-Schneider njll. Kwezinye izingxenye ezenziwe e-China, sikhetha imboni engcono kakhulu embonini futhi sisayine inkontileka yekhwalithi yomkhiqizo we-guranntee nabo, ukuze siqinisekise ukuthi zonke izingxenye zonke izingxenye esizisebenzisayo esithandweni ziyimikhiqizo engcono kakhulu yekhwalithi.

3. Ukuphathwa Kwekhwalithi Eqinile: Sinamaphuzu okuhlola ikhwalithi angu-8 ezinqubweni zokukhiqiza isithando somlilo, Ukuhlolwa endaweni yokuhlola ngayinye kuthathwa ngabasebenzi abangu-2 futhi umphathi wefekthri ongu-1 unesibopho salokho. Kula maphuzu okuhlola, izinto zokwakha kanye nezingxenye, nazo zonke izici zesithando somlilo zihlolwe kabili ukuze kuqinisekiswe ikhwalithi yayo. Ekugcineni, ngaphambi kokuba isithando somlilo siphume efektri, kufanele sihlolwe okokugcina ngokuhlolwa kokwelashwa kokushisa.