1. Ukuba nesibindi

Kunzima ukwenza i-ceramic kanye ne-ceramic, izingxenye ze-ceramic nezensimbi.Iningi le-solder lakha ibhola endaweni ye-ceramic, enokumanziswa okuncane noma okungamanzi.Insimbi yokugcwalisa ekwazi ukumanzisa i-ceramics kulula ukwenza inhlanganisela ye-brittle ehlukahlukene (njengama-carbides, ama-silicides nama-ternary noma ama-multivariate compounds) ekuxhumaneni okuhlangene ngesikhathi sokubhula.Ukuba khona kwalezi zinhlanganisela kuthinta izakhiwo zemishini zelunga.Ukwengeza, ngenxa yomehluko omkhulu wama-coefficients wokwandisa okushisayo phakathi kwe-ceramic, insimbi kanye ne-solder, kuzoba nokucindezeleka okusalayo ekuhlanganyeleni ngemva kokuba izinga lokushisa elivuthayo lipholile ekamelweni lokushisa, elingabangela ukuqhekeka okuhlangene.

Ukumanzisa kwe-solder ebusweni be-ceramic kungathuthukiswa ngokungeza izakhi zensimbi ezisebenzayo ku-solder evamile;Izinga lokushisa eliphansi kanye ne-brazing yesikhathi esifushane kunganciphisa umphumela wokusabela kwesixhumi esibonakalayo;Ukucindezeleka okushisayo okuhlangene kungancishiswa ngokuklama ifomu elihlangene elifanele futhi kusetshenziswe insimbi eyodwa noma eminingi yongqimba njengongqimba oluphakathi.

2. Solder

I-Ceramic nensimbi kuvame ukuxhunywa esithandweni se-vacuum noma i-hydrogen ne-argon furnace.Ngaphezu kwezimpawu ezijwayelekile, izinsimbi zokugcwalisa i-brazing zamadivayisi kagesi we-vacuum kufanele futhi zibe nezidingo ezikhethekile.Isibonelo, i-solder akufanele iqukathe izakhi ezikhiqiza umfutho we-vapor ophezulu, ukuze ungabangeli ukuvuza kwe-dielectric kanye ne-cathode poisoning yamadivayisi.Ngokuvamile kucaciswa ukuthi lapho idivayisi isebenza, ukucindezela komhwamuko we-solder akufanele kudlule i-10-3pa, futhi ukungcola okuphezulu komfutho womoya oqukethwe akumele kudlule u-0.002% ~ 0.005%;I-w (o) ye-solder akufanele idlule u-0.001%, ukuze ugweme umhwamuko wamanzi okhiqizwa ngesikhathi sokubhula i-hydrogen, engase ibangele ukuchaphazwa kwensimbi encibilikisiwe ye-solder;Ngaphezu kwalokho, i-solder kufanele ihlanzeke futhi ingabi nama-oxide angaphezulu.

Lapho i-brazing ngemuva kwe-ceramic metallization, ithusi, isisekelo, ithusi lesiliva, ithusi legolide nezinye izinsimbi zokugcwalisa i-alloy brazing zingasetshenziswa.

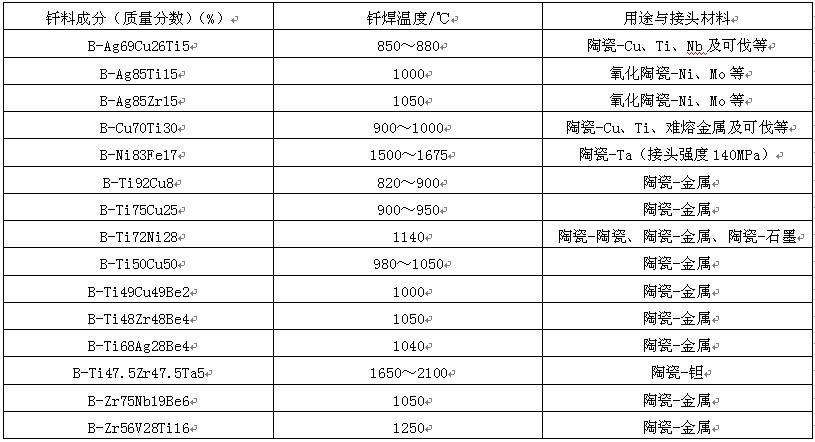

Ngokubhula okuqondile kwezitsha zobumba nezinsimbi, izinsimbi zokugcwalisa eziqukethe izakhi ezisebenzayo i-Ti ne-Zr zizokhethwa.Izinsimbi zokugcwalisa kanambambili ikakhulukazi i-Ti Cu kanye ne-Ti Ni, engasetshenziswa ku-1100 ℃.Phakathi kwe-ternary solder, i-Ag Cu Ti (W) (TI) iyi-solder esetshenziswa kakhulu, engasetshenziselwa ukubhula okuqondile kwezitsha zobumba nezinsimbi.I-ternary filler metal ingasetshenziswa nge-foil, powder noma i-Ag Cu eutectic filler metal ene-Ti powder.I-B-ti49be2 brazing filler metal inokumelana nokugqwala okufanayo kwensimbi engagqwali kanye nomfutho womoya ophansi.Kungakhethwa ngokukhethekile emalungeni okuvalwa kwe-vacuum nge-oxidation kanye nokumelana nokuvuza.Ku-ti-v-cr solder, izinga lokushisa elincibilikayo liphansi kakhulu (1620 ℃) uma i-w (V) ingu-30%, futhi ukungezwa kwe-Cr kunganciphisa ngempumelelo ibanga lokushisa elincibilikayo.I-solder ye-B-ti47.5ta5 ngaphandle kwe-Cr isetshenziselwe ukubhula okuqondile kwe-alumina ne-magnesium oxide, futhi ilunga layo lingasebenza ekushiseni kwe-ambient okungu-1000 ℃.Ithebula 14 libonisa ukuguquguquka okusebenzayo kokuxhumana okuqondile phakathi kwe-ceramic nensimbi.

Ithebula le-14 lensimbi esebenzayo yokugcwalisa i-brazing ye-ceramic ne-brazing yensimbi

2. Ubuchwepheshe be-Brazing

Amaceramics enziwe ngensimbi ngaphambili angagxilwa kugesi engabizi kakhulu, i-hydrogen noma imvelo yevacuum.I-vacuum brazing ngokuvamile isetshenziselwa ukubrasa okuqondile kwezitsha zobumba ngaphandle kwe-metalization.

(1) Inqubo yokubhinca yendawo yonke inqubo yokubrazisa yendawo yonke ye-ceramic nensimbi ingahlukaniswa ngezinqubo eziyisikhombisa: ukuhlanza indawo, ukunamathisela okunamathiselwe, i-ceramic surface metallization, i-nickel plating, i-brazing kanye nokuhlolwa kwe-post weld.

Inhloso yokuhlanza ingaphezulu ukususa ibala likawoyela, ibala lokujuluka kanye nefilimu ye-oxide ebusweni bensimbi eyisisekelo.Izingxenye zensimbi kanye ne-solder kufanele zihlanjululwe kuqala, bese ifilimu ye-oxide izosuswa ngokugeza kwe-asidi noma i-alkali, igezwe ngamanzi agelezayo futhi yomiswe.Izingxenye ezinezidingo eziphezulu zizophathwa ngokushiswa esithandweni se-vacuum noma esithandweni se-hydrogen (indlela ye-ion bombardment ingasetshenziswa) ezingeni lokushisa elifanele kanye nesikhathi sokuhlanza ubuso bezingxenye.Izingxenye ezihlanziwe akufanele zihlangane nezinto ezinamafutha noma izandla ezingenalutho.Zizofakwa ngokushesha kunqubo elandelayo noma kumshini wokomisa.Ngeke zivezwe emoyeni isikhathi eside.Izingxenye ze-Ceramic kufanele zihlanzwe nge-acetone ne-ultrasonic, zigezwe ngamanzi agelezayo, futhi ekugcineni zibiliswe kabili ngamanzi ahlanzekile imizuzu engu-15 isikhathi ngasinye.

Namathisela enamathela kuyinqubo ebalulekile metallization Ceramic.Ngesikhathi sokumboza, isetshenziswa endaweni ye-ceramic ukuze yenziwe insimbi ngebhulashi noma umshini wokunamathisela wokunamathisela.Ubukhulu bokunamathela ngokuvamile buyi-30 ~ 60mm.I-paste ngokuvamile ilungiswa ngempushana yensimbi ehlanzekile (ngezinye izikhathi i-oxide yensimbi efanelekile yengezwa) enosayizi wezinhlayiyana ezingaba ngu-1 ~ 5um kanye ne-organic adhesive.

Izingxenye ze-ceramic ezinamathiselwe zithunyelwa esithandweni se-hydrogen futhi zifakwe i-hydrogen emanzi noma i-ammonia ephukile ku-1300 ~ 1500 ℃ imizuzu engu-30 ~ 60min.Ezingxenyeni ze-ceramic ezinamekwe ngama-hydride, zizoshiswa cishe ku-900 ℃ ukuze zibole ama-hydride futhi zisabele ngensimbi emsulwa noma i-titanium (noma i-zirconium) esele endaweni ye-ceramic ukuze kutholwe ukunamathela kwensimbi endaweni yobumba.

Okwesendlalelo se-Metalized Mo Mn, ukuze sibe manzi ngesoda, ungqimba lwe-nickel luka-1.4 ~ 5um kufanele lufakwe ugesi noma lunamekwe ngongqimba lwempushana ye-nickel.Uma izinga lokushisa lokubhula lingaphansi kuka-1000 ℃, ungqimba lwe-nickel ludinga ukushiswa ngaphambili esithandweni se-hydrogen.Izinga lokushisa sintering nesikhathi 1000 ℃ /15 ~ 20min.

I-ceramics ephathwayo izingxenye zensimbi, ezizohlanganiswa zibe zizonke ngensimbi engagqwali noma i-graphite kanye nesikhunta se-ceramic.I-solder izofakwa emajoyintini, futhi i-workpiece izogcinwa ihlanzekile kulo lonke umsebenzi, futhi ngeke ithintwe ngezandla ezingenalutho.

Ukushisa kufanele kwenziwe esithandweni se-argon, i-hydrogen noma i-vacuum.Ukushisa kwe-brazing kuncike ku-brazing filler metal.Ukuze uvimbele ukuqhekeka kwezingxenye ze-ceramic, izinga lokupholisa akufanele lisheshe kakhulu.Ngaphezu kwalokho, i-brazing ingasebenzisa ingcindezi ethile (cishe 0.49 ~ 0.98mpa).

Ngokungeziwe ekuhlolweni kwekhwalithi yangaphezulu, izindawo zokushisela ezibrazed nazo zizoba ngaphansi kokushaqeka okushisayo nokuhlolwa kwempahla ngemishini.Izingxenye zokuvala zemishini ye-vacuum kufanele futhi zibe ngaphansi kokuhlolwa kokuvuza ngokuya ngemithetho efanele.

(2) Ukubrasa okuqondile lapho kubhuka ngokuqondile (indlela yensimbi esebenzayo), qala ngokuhlanza indawo yokushisela i-ceramic neyensimbi, bese uyazihlanganisa.Ukuze ugweme ukuqhekeka okubangelwa ama-coefficients ahlukene okunweba okushisayo kwezakhi zengxenye, isendlalelo se-buffer (ungqimba olulodwa noma ngaphezulu lwamashidi ensimbi) lungashintshwa phakathi kokushisela.I-brazing filler metal izoboshelwa phakathi kokushisela okubili noma ibekwe endaweni lapho igebe ligcwaliswa khona ngensimbi yokugcwalisa ebhulasi ngangokunokwenzeka, bese ukubhsa kuzokwenziwa njengokugqanyiswa kwe-vacuum okuvamile.

Uma i-Ag Cu Ti solder isetshenziselwa ukubhula okuqondile, indlela yokufaka i-vacuum brazing izokwamukelwa.Lapho i-vacuum degree esithandweni ifinyelela ku-2.7 × Qala ukushisa ngo-10-3pa, futhi izinga lokushisa lingakhuphuka ngokushesha ngalesi sikhathi;Uma izinga lokushisa liseduze nendawo yokuncibilika kwe-solder, izinga lokushisa kufanele liphakanyiswe kancane ukuze izinga lokushisa lazo zonke izingxenye ze-weldment lifane;Lapho i-solder incibilika, izinga lokushisa lizokhushulwa ngokushesha libe izinga lokushisa eliqinile, futhi isikhathi sokubamba sizoba ngu-3 ~ 5min;Ngesikhathi sokupholisa, izopholiswa kancane kancane ngaphambi kuka-700 ℃, futhi ingapholiswa ngokwemvelo ngesithando somlilo ngemva kuka-700 ℃.

Lapho i-Ti Cu esebenzayo i-solder iboshwe ngokuqondile, uhlobo lwe-solder ingaba i-Cu foil kanye ne-Ti powder noma izingxenye ze-Cu kanye ne-Ti foil, noma i-ceramic surface ingagcotshwa nge-Ti powder plus Cu foil.Ngaphambi kokugqama, zonke izingxenye zensimbi zizokhishwa nge-vacuum.Izinga lokushisa elikhipha umoya-mpilo lethusi elingenayo umoya-mpilo lizoba ngu-750 ~ 800 ℃, futhi i-Ti, Nb, Ta, njll. izokhishwa ku-900 ℃ imizuzu engu-15.Ngalesi sikhathi, i-vacuum degree akufanele ibe ngaphansi kuka-6.7 × 10-3Pa. Ngesikhathi sokubhula, hlanganisa izingxenye ezizoshiselwa endaweni, zishise esithandweni somlilo ku-900 ~ 1120 ℃, futhi isikhathi sokubamba ngu-2 ~ 5 imiz.Phakathi nayo yonke inqubo yokubhula, i-vacuum degree akufanele ibe ngaphansi kuka-6.7 × 10-3Pa.

Inqubo yokubrasa yendlela ye-Ti Ni ifana neyendlela ye-Ti Cu, futhi izinga lokushisa lokubhusa lingu-900 ± 10 ℃.

(3) Indlela ye-oxide brazing indlela ye-oxide brazing iyindlela yokuthola ukuxhumana okuthembekile ngokusebenzisa isigaba sengilazi esakhiwe ukuncibilika kwe-oxide solder ukuze ingene kumaceramics futhi imanzise ingaphezulu lensimbi.Ingakwazi ukuxhuma i-ceramics nge-ceramics kanye ne-ceramics ngezinsimbi.Izinsimbi ze-oxide brazing filler ikakhulukazi zakhiwe i-Al2O3, i-Cao, i-Bao ne-MgO.Ngokungeza i-B2O3, i-Y2O3 ne-ta2o3, izinsimbi zokugcwalisa ezinezingqimba ezihlukahlukene zokuncibilika kanye nama-coefficients okunwetshwa okuqondile angatholakala.Ngaphezu kwalokho, i-fluoride brazing filler metals ene-CaF2 ne-NaF njengezingxenye eziyinhloko ingase futhi isetshenziselwe ukuxhuma i-ceramics nezinsimbi ukuze kutholwe amalunga anamandla aphezulu kanye nokumelana nokushisa okuphezulu.

Isikhathi sokuthumela: Jun-13-2022