I-Brazing yensimbi engagqwali

1. Ukuba nesibindi

Inkinga eyinhloko ekuqiniseni insimbi engagqwali ukuthi ifilimu ye-oxide engaphezulu ithinta kakhulu ukumanziswa nokusabalala kwe-solder.Izinsimbi ezihlukahlukene ezingenasici ziqukethe inani elikhulu le-Cr, kanti ezinye ziqukethe i-Ni, Ti, Mn, Mo, Nb nezinye izakhi, ezingakha ama-oxide ahlukahlukene noma ngisho nama-oxide ayinhlanganisela phezulu.Phakathi kwazo, ama-oxide Cr2O3 kanye ne-TiO2 ye-Cr ne-Ti azinzile futhi kunzima ukuwasusa.Lapho kushaywa umoya, kufanele kusetshenziswe i-flux esebenzayo ukuze ibasuse;Lapho i-brazing emkhathini ovikelayo, ifilimu ye-oxide ingancishiswa kuphela emkhathini wokuhlanzeka okuphezulu ngamazolo aphansi kanye nokushisa okwanele;Ku-vacuum brazing, kuyadingeka ukuthi ube ne-vacuum eyanele kanye nezinga lokushisa elanele ukuze uzuze umphumela omuhle wokubhula.

Enye inkinga yokugaya insimbi engagqwali ukuthi izinga lokushisa lokushisa linomthelela omkhulu ekwakhiweni kwesisekelo sensimbi.Izinga lokushisa elishisayo lensimbi engenasici ye-austenitic akufanele libe ngaphezu kuka-1150 ℃, ngaphandle kwalokho okusanhlamvu kuzokhula ngokujulile;Uma insimbi engagqwali ye-austenitic ingenayo i-elementi ezinzile i-Ti noma i-Nb futhi inokuqukethwe kwekhabhoni ephezulu, ukugqama ngaphakathi kwezinga lokushisa lokuzwela (500 ~ 850 ℃) nakho kuzogwenywa.Ukuvimbela ukumelana nokugqwala ukuthi kwehle ngenxa yemvula ye-chromium carbide.Ukukhethwa kwezinga lokushisa eliqinile lensimbi engagqwali ye-martensitic kuqine kakhulu.Enye iwukufanisa ukushisa kwe-brazing nezinga lokushisa lokucisha, ukuze kuhlanganiswe inqubo yokushisa nenqubo yokwelapha ukushisa;Okunye ukuthi izinga lokushisa lokubilisa kufanele libe ngaphansi kwezinga lokushisa elishisayo ukuze uvimbele isisekelo sensimbi ukuthi singathamba ngesikhathi sokubhula.Umgomo wokukhetha izinga lokushisa elishisayo lemvula eyenza insimbi engagqwali ibe lukhuni iyafana naleyo yensimbi engagqwali ye-martensitic, okungukuthi, izinga lokushisa elibasayo kufanele lifane nesistimu yokwelapha ukushisa ukuze kutholwe izici ezingcono kakhulu zemishini.

Ngaphezu kwalezi zinkinga ezimbili eziyinhloko, kukhona ukuthambekela kokuqhekeka kwengcindezi lapho kubhula insimbi engagqwali ye-austenitic, ikakhulukazi lapho ubhusa ngensimbi yokugcwalisa i-zinc yethusi.Ukuze ugweme ukuqhekeka kwengcindezi, ucezu lomsebenzi luzosuswa ukucindezeleka ngaphambi kokubhuqa, futhi ucezu lomsebenzi kufanele lushiswe ngokufanayo ngesikhathi sokubhula.

2. I-brazing material

(1) Ngokwezidingo zokusetshenziswa kokushisela insimbi engagqwali, izinsimbi zokugcwalisa ezisetshenziswa kakhulu zokushisela insimbi engagqwali zifaka insimbi yokugcwalisa insimbi ye-Tin Lead, insimbi yokugcwalisa insimbi, insimbi yokugcwalisa i-brazing esekelwe ethusi, insimbi yokugcwalisa i-manganese, i-nickel esekelwe. i-brazing filler metal kanye nensimbi eyigugu yokugcwalisa insimbi.

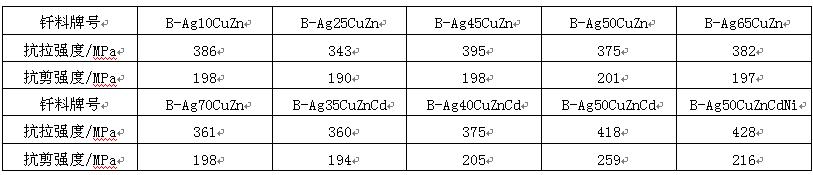

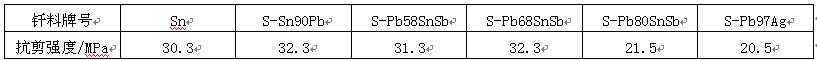

I-tin lead solder isetshenziswa kakhulu ekuhlanganiseni insimbi engagqwali, futhi ifaneleka ukuba nethayela eliphezulu.Ukuphakama kwe-tin ye-solder, kungcono ukumanzisa kwayo kunsimbi engagqwali.Amandla e-shear we-1Cr18Ni9Ti yensimbi engagqwali ehlanganiswe nama-solder amaningi avamile we-tin abhalwe kuThebula 3. Ngenxa yamandla aphansi ahlangene, asetshenziselwa kuphela izingxenye zokubhebheza ezinomthamo omncane wokuthwala.

Ithebula 3 lamandla okugunda we-1Cr18Ni9Ti insimbi engagqwali ehlangene eboshwe ngethayela eliholayo

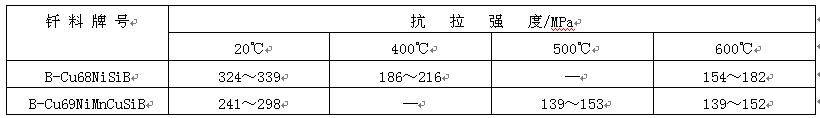

Izinsimbi zokugcwalisa ezisekelwe esiliva ziyizinsimbi zokugcwalisa ezivame ukusetshenziswa kakhulu zokubhula insimbi engagqwali.Phakathi kwazo, i-zinc yethusi yesiliva kanye nezinsimbi zethusi ze-zinc cadmium filler zisetshenziswa kakhulu ngoba izinga lokushisa elishisayo linomthelela omncane ezimpahleni zesisekelo sensimbi.Amandla ensimbi engagqwali ye-ICr18Ni9Ti eboshwe ngamasoda amaningana asekelwe esiliva asohlwini kuThebula 4. Amalunga ensimbi engagqwali aboshwe ngamasoda esiliva awavamile ukusetshenziswa emithonjeni egqwala kakhulu, futhi izinga lokushisa elisebenzayo lamalunga ngokuvamile alidluli ku-300 ℃. .Uma ubrasa insimbi engagqwali ngaphandle kwe-nickel, ukuze kugwenywe ukubola kwelunga eliqinile endaweni eswakeme, kuzosetshenziswa insimbi yokugcwalisa ene-nickel eyengeziwe, njenge-b-ag50cuzncdni.Lapho kubhula insimbi engagqwali ye-martensitic, ukuze kuvinjelwe ukuthamba kwesisekelo sensimbi, kuzosetshenziswa insimbi yokugcwalisa enezinga lokushisa elingeqile ku-650 ℃, njenge-b-ag40cuzncd.Uma ubrasa insimbi engagqwali endaweni evikelayo, ukuze kukhishwe ifilimu ye-oxide ngaphezulu, i-lithium equkethe i-self brazing flux ingasetshenziswa, njenge-b-ag92culi ne-b-ag72culi.Lapho ubhusa insimbi engagqwali ku-vacuum, ukuze wenze i-filler metal isenayo ukumanzisa okuhle uma ingenayo izakhi ezifana ne-Zn ne-CD okulula ukuhwamuka, insimbi yokugcwalisa isiliva equkethe izakhi ezifana ne-Mn, i-Ni ne-RD ingaba kukhethiwe.

Ithebula 4 lamandla e-ICr18Ni9Ti yensimbi engagqwali ehlanganiswe ngensimbi yokugcwalisa esekwe esiliva

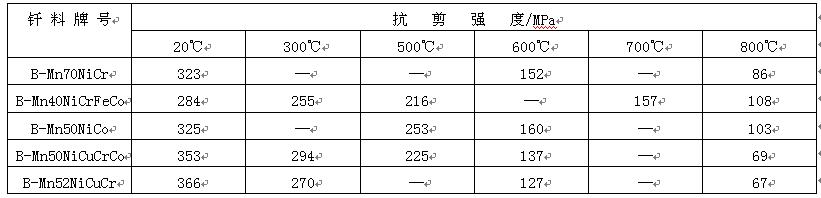

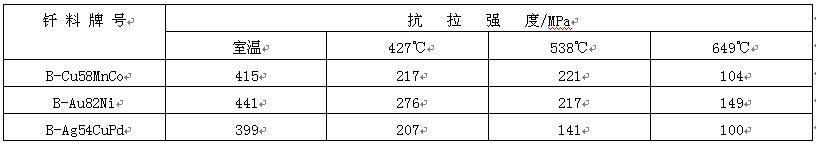

Izinsimbi zokugcwalisa ezisekelwe e-Copper ezisetshenziselwa ukubhula izinsimbi ezihlukene ikakhulukazi ziyithusi elimsulwa, i-nickel yethusi nezinsimbi zethusi ze-manganese cobalt brazing filler.Insimbi yokugcwalisa i-copper brazing ehlanzekile isetshenziselwa ikakhulukazi ukubhula ngaphansi kokuvikelwa kwegesi noma i-vacuum.Izinga lokushisa elisebenzayo lensimbi engagqwali alikho ngaphezu kuka-400 ℃, kodwa ilunga alinamandla okumelana ne-oxidation.I-copper nickel brazing filler metal isetshenziselwa ikakhulukazi ukubhula amalangabi kanye nokubhula kwe-induction.Amandla e-brazed 1Cr18Ni9Ti yensimbi engagqwali aboniswa kuThebula 5. Kungabonakala ukuthi isihlanganisi sinamandla afanayo nesisekelo sensimbi, futhi izinga lokushisa lokusebenza liphezulu.I-Cu Mn co brazing filler metal isetshenziselwa ikakhulukazi ukubrasa insimbi engagqwali ye-martensitic endaweni evikelayo.Amandla ahlangene nezinga lokushisa lokusebenza kuqhathaniswa nalawo ahlanganiswe nensimbi yokugcwalisa esekwe egolide.Isibonelo, inhlanganisela yensimbi engagqwali engu-1Cr13 eboshwe ngesolder ye-b-cu58mnco inokusebenza okufanayo nokuhlangene okufanayo kwensimbi engenasici eboshwe ngesolder ye-b-au82ni (bona Ithebula 6), kodwa izindleko zokukhiqiza zehliswe kakhulu.

Ithebula 5 lamandla e-shear we-1Cr18Ni9Ti ehlangene yensimbi engenasici eboshwe ngezinga lokushisa eliphezulu lensimbi yethusi

Ithebula 6 lamandla okugunda we-1Cr13 insimbi engagqwali ehlangene ehlanganisiwe

Izinsimbi zokugcwalisa i-manganese ezisekelwe ku-brazing zisetshenziselwa ikakhulukazi ukubhula okuvikelwe kwegesi, futhi ubumsulwa begesi kudingeka bube phezulu.Ukuze ugweme ukukhula okusanhlamvu kwesisekelo sensimbi, kufanele kukhethwe insimbi ehambisanayo yokugcwalisa i-brazing enezinga lokushisa elingaphansi kuka-1150 ℃.Umphumela ogculisayo wokubhoda ungatholakala kumajoyinti ensimbi engagqwali ahlanganiswe ne-manganese esekelwe solder, njengoba kukhonjisiwe kuThebula 7. Izinga lokushisa elisebenzayo lokuhlanganisa lingafinyelela ku-600 ℃.

Ithebula 7 lamandla e-shear ye-lcr18ni9fi yensimbi engagqwali ehlanganiswe nensimbi yokugcwalisa esekwe manganese

Lapho insimbi engagqwali igaywa ngensimbi ye-nickel base filler, ilunga lisebenza kahle izinga lokushisa eliphezulu.Le nsimbi yokugcwalisa imvamisa isetshenziselwa i-brazing evikelwe ngegesi noma i-vacuum brazing.Ukuze unqobe inkinga yokuthi ama-brittle compounds amaningi akhiqizwa ekuhlanganyeleni okuqinile ngesikhathi sokuhlangana, okunciphisa kakhulu amandla kanye ne-plasticity yejoyinti, igebe elihlangene kufanele lincishiswe ukuze kuqinisekiswe ukuthi izakhi zilula ukwakha isigaba se-brittle i-solder isakazwe ngokugcwele ku-base metal.Ukuze uvimbele ukuvela kokukhula okusanhlamvu kwesisekelo sensimbi ngenxa yokubamba isikhathi eside ekushiseni okushisayo, izinyathelo zenqubo yokubamba isikhathi esifushane kanye nokwelashwa kokusabalalisa ekushiseni okuphansi (uma kuqhathaniswa nokushisa kwe-brazing) ngemva kokushisela kungathathwa.

Izinsimbi zokugcwalisa zensimbi eziqinile ezisetshenziselwa ukubraziza insimbi engagqwali ikakhulukazi zifaka izinsimbi zokugcwalisa ezisekelwe egolideni kanye ne-palladium equkethe izinsimbi zokugcwalisa, okuyi-b-au82ni, b-ag54cupd ne-b-au82ni, ezinokumanzisa okuhle.I-brazed stainless steel joint inamandla okushisa aphezulu kanye nokumelana ne-oxidation, futhi izinga lokushisa eliphezulu lokusebenza lingafinyelela ku-800 ℃.I-B-ag54cupd inezici ezifanayo ne-b-au82ni futhi intengo yayo iphansi, ngakho ivamise ukufaka esikhundleni se-b-au82ni.

(2) Ingaphezulu lensimbi engagqwali ekuguqukeni nasemoyeni wesithando somlilo liqukethe ama-oxide afana ne-Cr2O3 ne-TiO2, engasuswa kuphela ngokusebenzisa i-flux enomsebenzi oqinile.Uma insimbi engagqwali igaywa nge-tin lead solder, i-flux efanelekile iyisisombululo se-aqueous phosphoric acid noma isixazululo se-zinc oxide hydrochloric acid.Isikhathi sokusebenza se-phosphoric acid aqueous solution sifushane, ngakho-ke indlela yokubrasa yokushisa okusheshayo kufanele yamukelwe.I-Fb102, fb103 noma i-fb104 fluxes ingasetshenziselwa ukubrasa insimbi engagqwali ngezinsimbi zokugcwalisa ezisekelwe esiliva.Lapho ubrasa insimbi engagqwali ngensimbi yokugcwalisa esekwe ethusi, i-fb105 flux isetshenziswa ngenxa yezinga lokushisa eliphakeme lokubhuqa.

Lapho ubhusa insimbi engagqwali esithandweni, umoya wevacuum noma umkhathi ovikelayo njenge-hydrogen, i-argon ne-ammonia yokubola kuvame ukusetshenziswa.Ngesikhathi se-vacuum brazing, ingcindezi ye-vacuum izoba ngaphansi kuka-10-2Pa.Uma iqhwa endaweni evikelayo, indawo yamazolo yegesi akumele ibe ngaphezu kuka -40 ℃ Uma ukuhlanzeka kwegesi kunganele noma izinga lokushisa eliqinile lingekho phezulu, inani elincane legesi yokubhula igesi, njenge-boron trifluoride, lingakwazi. kwengezwe emkhathini.

2. Ubuchwepheshe be-Brazing

Insimbi engagqwali kufanele ihlanzwe ngokuqinile ngaphambi kokubhuqa ukuze kukhishwe noma yimaphi amafutha kanye nefilimu kawoyela.Kungcono ukugcoba ngokushesha ngemva kokuhlanza.

Ukubhula kwensimbi engagqwali kungathatha amalangabi, induction kanye nezindlela zokushisa okuphakathi kwesithando somlilo.Isithando somlilo sokubhula esithandweni kufanele sibe nesistimu yokulawula izinga lokushisa elihle (ukuchezuka kwezinga lokushisa lokubilisa kuyadingeka ukuthi libe ± 6 ℃) futhi lingapholiswa ngokushesha.Lapho i-hydrogen isetshenziswa njengegesi evikela ukugandaya, izimfuneko ze-hydrogen zincika ekushiseni okushisayo nasekubunjweni kwensimbi eyisisekelo, okungukuthi, lapho izinga lokushisa liphansi, kulapho isisekelo sensimbi siba ne-stabilizer, namazolo ayancipha. iphuzu le-hydrogen liyadingeka.Isibonelo, ezinsimbi ezingenasici ze-martensitic ezifana ne-1Cr13 kanye ne-cr17ni2t, uma ibhusa ngo-1000 ℃, indawo yamazolo ye-hydrogen idingeka ukuthi ibe ngaphansi kuka -40 ℃;Ngensimbi engagqwali engu-18-8 chromium nickel ngaphandle kokuzinzisa, indawo yamazolo e-hydrogen izoba ngaphansi kuka-25 ℃ ngesikhathi sokubhuqa ku-1150 ℃;Kodwa-ke, ku-1Cr18Ni9Ti insimbi engagqwali equkethe i-titanium stabilizer, indawo yamazolo e-hydrogen kumele ibe ngaphansi kuka -40 ℃ uma ibhuka ku-1150 ℃.Lapho i-brazing ngokuvikelwa kwe-argon, ukuhlanzeka kwe-argon kuyadingeka ukuba kube phezulu.Uma ithusi noma i-nickel ifakwe ebusweni bensimbi engagqwali, imfuneko yokuhlanzeka kwegesi yokuvikela ingancishiswa.Ukuze uqinisekise ukususwa kwefilimu ye-oxide ebusweni bensimbi engagqwali, i-BF3 gas flux nayo ingangezwa, futhi i-lithium noma i-boron equkethe i-self flux solder ingasetshenziswa.Uma i-vacuum brazing insimbi engagqwali, izimfuneko zedigri ye-vacuum zincike ekushiseni okushisayo.Ngokukhuphuka kwezinga lokushisa lokubhoboza, i-vacuum edingekayo ingancishiswa.

Inqubo eyinhloko yensimbi engagqwali ngemva kokubhula ukuhlanza ukugeleza okusele kanye ne-residual flow inhibitor, futhi kwenziwe ukwelashwa kokushisa kwe-post brazing uma kunesidingo.Ngokuya ngendlela yokuguquguquka kanye ne-brazing esetshenzisiwe, i-flux eyinsalela ingawashwa ngamanzi, ihlanzwe ngomshini noma ihlanzwe ngamakhemikhali.Uma i-abrasive isetshenziselwa ukuhlanza i-flux eyinsalela noma ifilimu ye-oxide endaweni eshisayo eduze kwejoyinti, isihlabathi noma ezinye izinhlayiya ezingenasici zensimbi zizosetshenziswa.Izingxenye ezenziwe ngensimbi engagqwali ye-martensitic kanye nemvula eqinisa insimbi engagqwali zidinga ukwelashwa ngokushisa ngokuya ngezidingo ezikhethekile zezinto ngemuva kokubhula.Amajoyinti ensimbi engagqwali aboshwe ngezinsimbi zokugcwalisa ze-Ni Cr B kanye ne-Ni Cr Si ngokuvamile aphathwa ngokwelashwa kokushisa okusakazwayo ngemva kokubhuqa ukuze kuncishiswe izidingo zegebe lokubhula futhi kuthuthukiswe i-microstructure kanye nezakhiwo zamalunga.

Isikhathi sokuthumela: Jun-13-2022