I-vacuum Debinding and Sintering furnace (Isithando se-MIM, isithando somlilo se-Metallurgy)

Izici

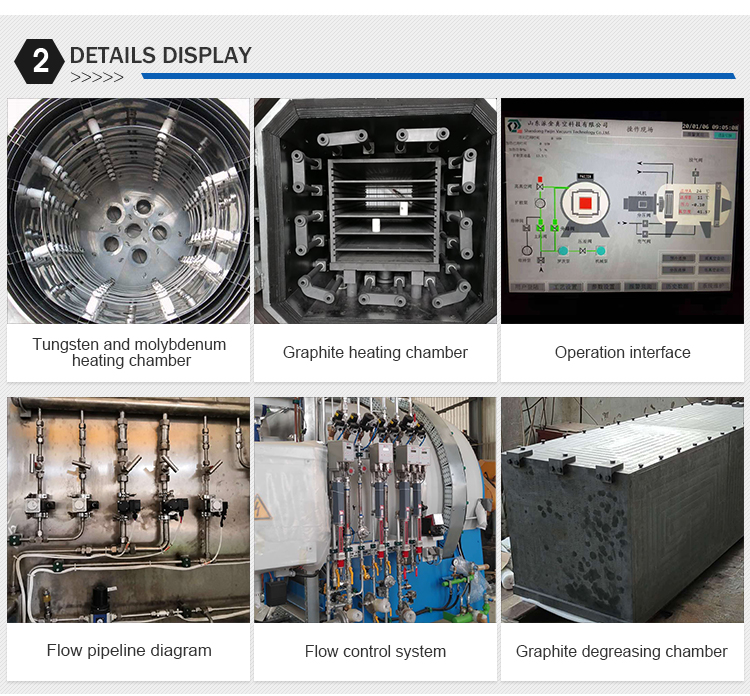

1. Isikrini sokufakwa kwe-graphite / isikrini sensimbi ngokuzikhethela, isici sokushisisa esingu-360 degree sizungeze ukushisisa ngemisebe, idizayini yokufaka ethembekile.

2. Ukushisa okuphezulu okufanayo nokusebenza kahle kokushisa

3. Vacuum ukucindezela okuyingxenye / umsebenzi wokulawula izinga lokushisa ezindaweni eziningi.

4. Imishini ezenzakalelayo ngokuphelele, ukuphepha okuphelele kanye nesistimu ye-alamu engajwayelekile.

5. Ukulawulwa kwenqubo okunembile ukuze kuzuzwe izinga lengxenye engaguquki nokuvimbela ukungcoliswa kwezingxenye nezindawo ezishisayo.

6. Ngebhokisi lokukhipha amafutha elivaliwe kanye ne-vacuum condenser ukunciphisa ukungcoliswa kwegumbi lokushisa kanye neyunithi.

7.Vimbela ukungcola ezingxenyeni zomlilo. Ibhokisi lokukhipha amafutha eliyisikwele lisetshenziselwa ukubhekana nenani elikhulu lezithasiselo zokubumba.

8. Inemisebenzi yokukhipha i-vacuum eguquguqukayo, i-vacuum sintering, i-micro-positive pressure sintering nokunye.

9. Isakhiwo sakamuva se-thermal insulation kanye nezinto ezisetshenziswayo, ukumelana nokucindezela kunamandla, futhi ukonga amandla kusobala.

I-10.Inomsebenzi we-alamu ye-overtemperature kanye ne-overpressure, ukuvikelwa kokucindezela okuzenzakalelayo okuzenzakalelayo, okuzenzakalelayoukuvikelwa kokukhululeka kokucindezela ngokweqile, ukuhlangana kwesenzo nokunye, ukuphepha kwemishini ephezulu.

11.Ukusebenza kwesilawuli kude, ukuxilongwa kwephutha elikude kanye nemisebenzi yokuthuthukisa isofthiwe ekude, njll.

Ukucaciswa kwemodeli ejwayelekile kanye nemingcele

| Imodeli | I-PJSJ-gr-30-1600 | I-PJSJ-gr-60-1600 | I-PJSJ-gr-100-1600 | I-PJSJ-gr-200-1600 | I-PJSJ-gr-450-1600 |

| Indawo eshisayo esebenzayo LWH (mm) | 200*200*300 | 300*300* 600 | 300*300* 900 | 400*400* 1200 | 500*500* 1800 |

| Isisindo somthwalo(kg) | 100 | 200 | 400 | 600 | 10000 |

| Amandla okushisa (kw) | 65 | 80 | 150 | 200 | 450 |

| Izinga lokushisa eliphezulu(℃) | 1600 | ||||

| Ukunemba kokulawula izinga lokushisa(℃) | ±1 | ||||

| Ukufana kwezinga lokushisa kwesithando somlilo(℃) | ±3 | ||||

| Idigri ye-vacuum yomsebenzi (Pa) | 4.0 * E -1 | ||||

| Amanani okumpompa (kuya ku-5 pa) | ≤10 amaminithi | ||||

| Izinga lokunyusa ingcindezi (Pa/H) | ≤ 0.5 | ||||

| Isilinganiso sokukhokhisa | >97.5% | ||||

| Indlela yokukhipha | N2 ekucindezelweni okungekuhle, H2 emkhathini | ||||

| Faka igesi | N2,H2,Alu | ||||

| Indlela yokupholisa | ukupholisa igesi ye-inert | ||||

| Indlela ye-Sintering | I-vacuum sintering, ingcindezi eyingxenye ye-sintering, i-sinteringless sintering | ||||

| Ukwakhiwa kwesithando somlilo | Igumbi elivundlile, elilodwa | ||||

| Indlela yokuvula umnyango wesithando somlilo | Uhlobo lwehinge | ||||

| Izakhi zokushisa | Izakhi zokushisa ze-Graphit | ||||

| Igumbi lokushisisa | Isakhiwo se-Graphit esizwakala kanzima nesithambile | ||||

| Thermocouple | C Uhlobo | ||||

| I-PLC nezinto zikagesi | Siemens | ||||

| Isilawuli sezinga lokushisa | EUROTHERM | ||||

| Iphampu ye-vacuum | Iphampu yemishini kanye nepompo yezimpande | ||||

| Ububanzi ongazikhethela obungokwezifiso | |||||

| Izinga lokushisa eliphezulu | 1300-2800 ℃ | ||||

| Izinga lokushisa eliphezulu | 6.7 * E -3 Pa | ||||

| Ukwakhiwa kwesithando somlilo | Igumbi elivundlile, eliqondile, Elilodwa | ||||

| Indlela yokuvula umnyango | Uhlobo lwehinge, uhlobo lokuphakamisa, uhlobo oluyisicaba | ||||

| Izakhi zokushisa | Izinto zokushisisa ze-Graphit, izinto zokushisisa ze-Mo | ||||

| Igumbi lokushisisa | I-graphit ehlanganisiwe izwakele, Sonke isikrini esibonisa insimbi | ||||

| Vacuum amaphampu | Ipompo yemishini kanye nepompo yezimpande; Mechanical, Roots kanye namaphampu okusabalalisa | ||||

| I-PLC nezinto zikagesi | Siemens; u-Omron; I-Mitsubishi; Siemens | ||||

| Isilawuli sezinga lokushisa | EUROTHERM;S HIMADEN | ||||